In a significant stride towards enhancing the durability and efficiency of nuclear energy systems, researchers have uncovered the profound impact of heat treatment on the microstructure and corrosion resistance of a promising steel alloy. The study, led by Qian Zheng from Guangdong Ocean University and Lanzhou University of Technology, focuses on oxide dispersion strengthened 316L (ODS-316L) steel, a candidate material for fourth-generation nuclear reactors. The findings, published in the Journal of Materials Research and Technology, offer valuable insights into optimizing the performance of nuclear-grade components.

The research delves into the intricate relationship between heat treatment (HT) temperatures and the microstructural evolution of ODS-316L alloys, which are prepared using laser powder bed fusion (LPBF) technology. This advanced manufacturing technique is pivotal in creating complex, high-performance components for the energy sector.

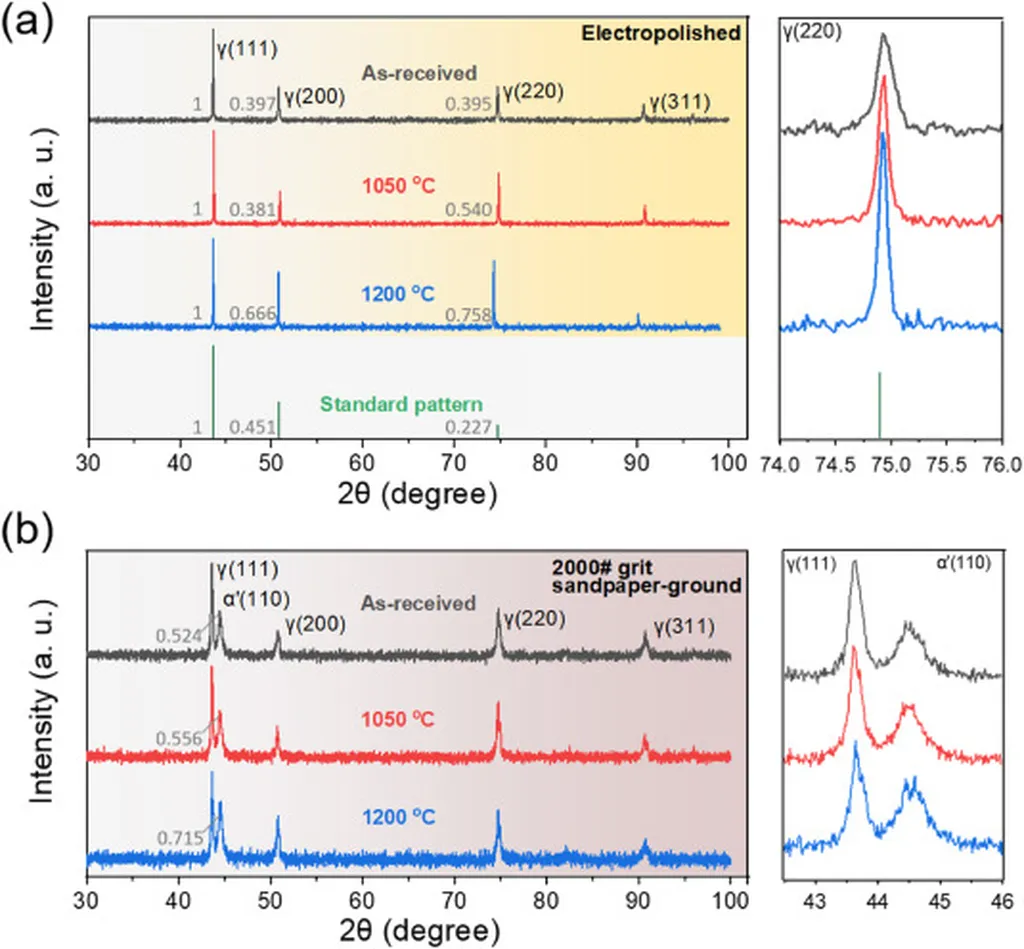

“Our study reveals that heat treatment can significantly regulate the microstructure of ODS-316L alloys,” Zheng explains. The team discovered that as the HT temperature increases, the characteristic fish-scale molten pool morphology of the as-fabricated alloy disappears, and recrystallized grains coarsen. At a HT temperature of 1150°C, the grain size reaches a maximum of 43.1 micrometers, with the proportion of low-angle grain boundaries peaking at 76.7%.

This microstructural evolution translates into enhanced corrosion resistance, a critical factor for materials used in the harsh environments of nuclear reactors. At 1150°C, the alloy exhibits exceptional corrosion resistance, with the self-corrosion potential reaching a maximum of -0.255 V and the self-corrosion current density decreasing to a minimum of 7.797 × 10⁻⁷ A/cm². The pitting potential and passivation interval also reach their maximum values, indicating a significant improvement in the material’s ability to withstand corrosive environments.

The study further identifies the formation of two types of nano-oxide particles, Y–Si–O and Si–O, uniformly distributed in the 316L matrix at this optimal heat treatment temperature. These nano-oxides play a crucial role in reducing the self-corrosion current density, thereby enhancing the alloy’s corrosion resistance.

The implications of this research are far-reaching for the energy sector. By optimizing the heat treatment processes for ODS-316L alloys, manufacturers can produce more durable and efficient components for next-generation nuclear reactors. This not only extends the lifespan of critical infrastructure but also reduces maintenance costs and improves overall safety.

“Our findings provide a theoretical basis and reference value for further optimizing the microstructure and corrosion resistance of nuclear-grade ODS-316L alloy components,” Zheng notes. This work paves the way for future developments in materials science and engineering, particularly in the realm of advanced nuclear energy systems.

As the world continues to seek sustainable and reliable energy solutions, the insights gained from this study will be instrumental in shaping the future of nuclear technology. By pushing the boundaries of material performance, researchers are not only advancing scientific knowledge but also contributing to a cleaner, more efficient energy landscape.