In the heart of Madrid, Spain, at the Centro de Investigaciones Energéticas, Medioambientales y Tecnológicas (CIEMAT), a groundbreaking project is taking shape. The International Fusion Materials Irradiation Facility (IFMIF) DONES is not your average energy project. It’s a first-of-its-kind facility designed to test materials for future fusion reactors, and it’s pushing the boundaries of logistics and maintenance in the energy sector.

F. Arranz, lead author of a recent study published in the journal *Nuclear Fusion*, explains that the IFMIF DONES project is a unique challenge. “The facility’s irradiation characteristics, combined with its mix of scientific prototypes and conventional equipment, make it unlike anything we’ve seen before,” Arranz says. The operational cycle, focused on material irradiation campaigns, is a stark contrast to typical industrial production cycles, adding another layer of complexity to the project.

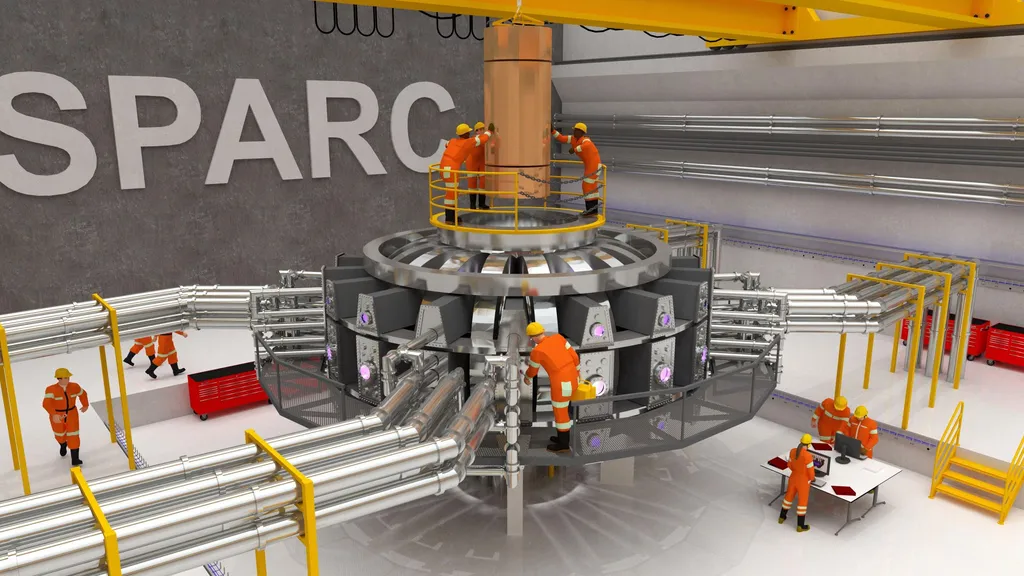

The team at CIEMAT has tackled this complexity head-on, developing innovative solutions in three main areas: virtual reality (VR) tools, maintenance policy, and logistics. The VR tools, developed using a video-game engine, are a game-changer. They allow the team to simulate and analyze critical maintenance operations in detail. “We’ve created interactive simulations where users can operate virtual equipment, like bridge cranes or transport platforms, using peripheral devices,” Arranz explains. This not only enhances safety but also improves efficiency, as potential issues can be identified and addressed before they become real problems.

The maintenance policy developed for IFMIF DONES is equally impressive. It outlines clear objectives and includes a comprehensive Maintenance Manual. Preventive maintenance operations are organized in a spreadsheet known as the Maintenance Matrix, ensuring that every aspect of the facility is kept in optimal condition.

Logistics is another area where the IFMIF DONES project is breaking new ground. The team has chosen modular omnidirectional platforms for transportation within the main building, a decision that has been carefully analyzed and justified. They’ve also identified solutions for transportation between buildings and handling extremely heavy elements. “We’ve even analyzed the interaction of transport with architectural features and proposed solutions to remove clashes,” Arranz says.

The implications of this research for the energy sector are significant. As we move towards a future powered by fusion energy, facilities like IFMIF DONES will be crucial in testing and developing the materials needed for fusion reactors. The innovative logistics and maintenance solutions developed by the team at CIEMAT could pave the way for similar advancements in other energy projects.

In the words of F. Arranz, “This project is not just about advancing fusion energy. It’s about pushing the boundaries of what’s possible in logistics and maintenance, and that has implications for the entire energy sector.” As the IFMIF DONES project continues to progress, it will be fascinating to see how these innovations shape the future of energy.