In a significant stride towards advancing biomaterials for cranial reconstruction, researchers have developed a novel ceramic-titanium matrix composite that promises enhanced protection and biocompatibility. The study, led by Walid M. Daoush from the Department of Chemistry at Imam Mohammad ibn Saud Islamic University (IMSIU), explores the potential of Al2O3 short fibers/Ti-12Mo-6Zr composites, published in the Journal of Materials Science: Materials in Medicine.

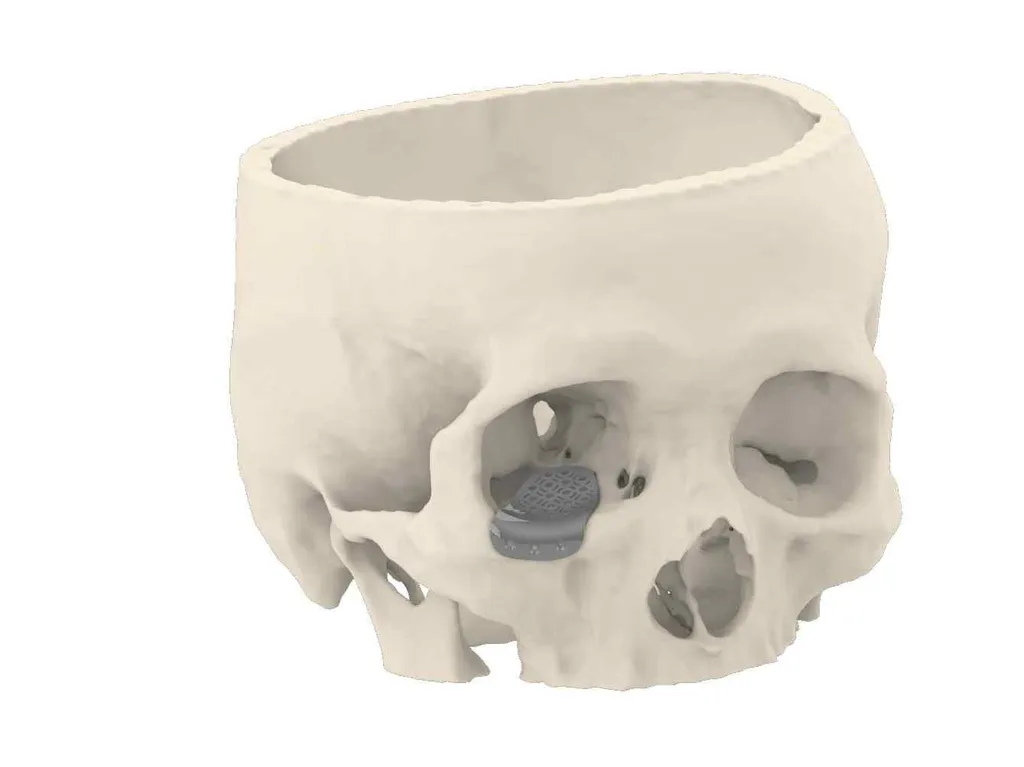

The research focuses on the synthesis and characterization of these composites using Spark Plasma Sintering (SPS), a technique that allows for the creation of complex and irregularly shaped parts essential for cranial reconstruction and maxillofacial trauma applications. “The addition of alumina short fibers significantly enhances the mechanical properties of the Ti-12Mo-6Zr matrix,” Daoush explains. “This improvement is crucial for applications that require materials to withstand external forces and resist infections.”

The team fabricated composites with varying concentrations of Al2O3 short fibers, up to 5 weight percent, and subjected them to extensive analysis. Using techniques such as optical microscopy, high-resolution scanning electron microscopy, and X-ray diffraction, they evaluated the microstructure, chemical composition, and phase identification of the samples. The nanomechanical properties were assessed through nanoindentation measurements, revealing that both hardness and Young’s modulus increased with the Al2O3 content.

“The results indicate that the produced composites have excellent mechanical properties, making them suitable for cranial reconstruction applications,” Daoush notes. “The efficiency of the SPS process in achieving these properties is a significant advancement in the field of biomaterials.”

The implications of this research extend beyond medical applications, offering potential benefits for the energy sector as well. The development of materials with superior mechanical and corrosion properties can lead to more durable and reliable components in energy infrastructure, from pipelines to power generation equipment. As the demand for sustainable and efficient energy solutions grows, the need for advanced materials that can withstand harsh environments becomes increasingly critical.

This study not only highlights the potential of Al2O3 short fibers/Ti-12Mo-6Zr composites in medical applications but also paves the way for innovative solutions in the energy sector. The findings suggest that further exploration of these materials could lead to breakthroughs in both fields, driving progress towards a future where advanced materials play a pivotal role in enhancing human health and energy sustainability.