In the relentless pursuit of harnessing fusion energy, scientists are continually exploring innovative materials that can withstand the extreme conditions within fusion reactors. A recent study published in the Journal of Nuclear Engineering, titled “Thermal Shock and Synergistic Plasma and Heat Load Testing of Powder Injection Molding Tungsten-Based Alloys,” offers promising insights into the potential of tungsten-based alloys produced via powder injection molding (PIM). This research, led by Mauricio Gago from the Forschungszentrum Jülich in Germany, could significantly impact the future of fusion reactor design and commercial energy production.

Fusion reactors, like the International Thermonuclear Experimental Reactor (ITER), require materials that can endure intense heat and plasma loads. Traditional ITER-grade tungsten has been the go-to choice, but it has limitations, particularly in terms of ductility and resistance to cracking. Gago and his team set out to test six different tungsten-based alloys produced using PIM, a method that allows for the creation of nearly net-shaped samples. These alloys included W-1TiC, W-2Y2O3, W-3Re-1TiC, W-3Re-2Y2O3, W-1HfC, and W-1La2O3-1TiC.

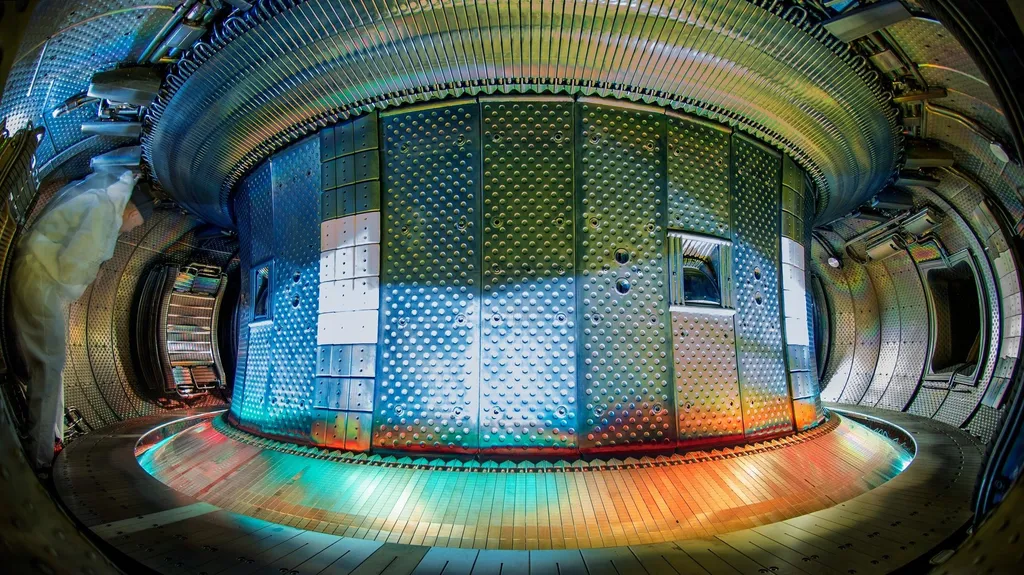

The tests were conducted using the PSI-2 linear plasma device, which simulates the conditions within a fusion reactor. The alloys were subjected to ITER-relevant plasma and heat loads to assess their performance. “All materials showed good behavior when exposed to the lower pulse number tests,” Gago explained. “However, standard tungsten performed slightly better, with no observable difference in surface roughness.”

The real test came with high-power shots, specifically one laser pulse of 1.6 GWm−2. Here, the researchers found that samples containing yttria were more prone to melting and droplet ejection. This insight is crucial for understanding the limitations of certain alloy compositions in high-stress environments.

Perhaps the most significant finding was observed after high pulse number tests (10,000 and 100,000 pulses), with and without plasma. The reference tungsten showed the most cracking and highest surface roughness of all materials, while the PIM samples demonstrated a higher resistance to cracking. This resistance can be attributed to the higher ductility of these alloys, particularly those containing rhenium.

The implications of this research are profound for the energy sector. As Gago noted, “Tungsten-based alloys, whether produced via PIM or other methods, could potentially be used in certain areas of a fusion reactor.” This suggests that PIM could be a viable method for producing materials that are not only cost-effective but also more resilient under extreme conditions.

The commercial impact of this research is substantial. Fusion energy, if successfully harnessed, could provide a nearly limitless source of clean energy. The development of more durable and ductile materials like those explored in this study could accelerate the commercialization of fusion reactors, making them a more viable option for global energy production.

As the world continues to seek sustainable and efficient energy solutions, the work of Gago and his team at the Forschungszentrum Jülich offers a beacon of hope. Their research, published in the Journal of Nuclear Engineering, underscores the importance of material science in the quest for fusion energy and highlights the potential of PIM-produced tungsten-based alloys to revolutionize the energy sector.