In the quest for efficient and sustainable energy sources, shale gas has emerged as a critical player, driving the global energy transition. However, the industry faces significant challenges, particularly in optimizing fracturing techniques to enhance production while minimizing interference between wells. A groundbreaking study led by Fushen Liu from the Research Center of Coastal and Urban Geotechnical Engineering at Zhejiang University sheds new light on these issues, offering insights that could reshape fracturing practices in the shale gas sector.

Published in the journal Energies, the study focuses on zipper fracturing, a technique widely used to stimulate shale reservoirs by creating complex fracture networks. The research highlights the growing problem of fracture-driven interactions (FDIs), which have intensified due to reduced well spacing and increased injection intensity. These interactions can lead to early production decline and well integrity issues, posing substantial economic and operational challenges for energy companies.

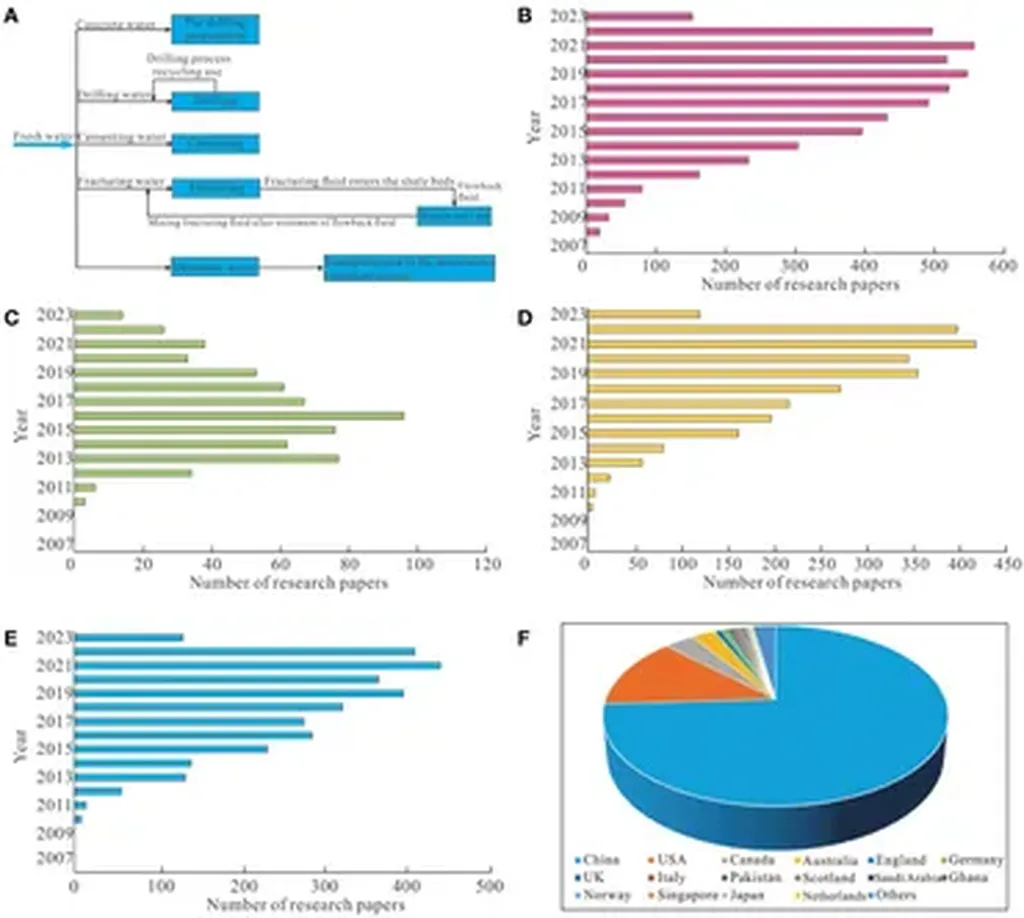

Liu and his team developed a fully coupled hydro–mechanical–damage (HMD) numerical model incorporating an explicit discrete fracture network (DFN). This advanced model captures the nonlinear mechanical behavior of natural fractures and their role in FDIs. “Our model allows us to simulate the opening and closure of fractures and their impact on permeability, providing a comprehensive understanding of the fracturing process,” Liu explained.

The study’s findings are particularly relevant for the energy sector. For instance, the research shows that when the horizontal differential stress exceeds 12 MPa, fractures tend to propagate as single dominant planes. This increases the risk of FDIs and reduces the effective stimulated reservoir volume (SRV). “This stress threshold is crucial for operators to consider when designing fracturing strategies,” Liu noted.

The study also reveals that increasing well spacing from 60 meters to 110 meters can delay or eliminate FDIs, significantly improving reservoir stimulation. Additionally, the fracture approach angle governs the interaction mechanisms between hydraulic and natural fractures, influencing the deflection and branching behavior of primary fractures. The injection rate, meanwhile, exerts a dual influence on fracture extension and FDI risk, requiring a delicate balance between stimulation efficiency and interference control.

These insights could have profound implications for the energy sector. By optimizing fracturing designs based on the study’s findings, companies can enhance production efficiency, reduce operational costs, and minimize environmental impacts. “Our work enriches the multi-physics coupling theory of FDIs during fracturing processes, providing a robust framework for better understanding and optimizing fracturing design in shale gas production,” Liu said.

As the energy sector continues to evolve, research like Liu’s will be instrumental in driving innovation and sustainability. By leveraging advanced modeling techniques and a deeper understanding of fracture mechanics, the industry can unlock new opportunities for efficient and responsible shale gas development. This study not only advances our scientific knowledge but also paves the way for more effective and environmentally conscious energy practices.