In the bustling world of offshore wind energy, where the relentless sea air meets towering turbines, a new study is making waves. Researchers from the Ocean University of China and Shandong Iron & Steel Group Co., Ltd. have been delving into the behavior of S460 steel, a high-strength, low-alloy material that’s increasingly popular in wind power equipment. Their findings, published in the journal *Materials Protection* (Cailiao Baohu), could significantly influence how we approach the design and maintenance of offshore structures.

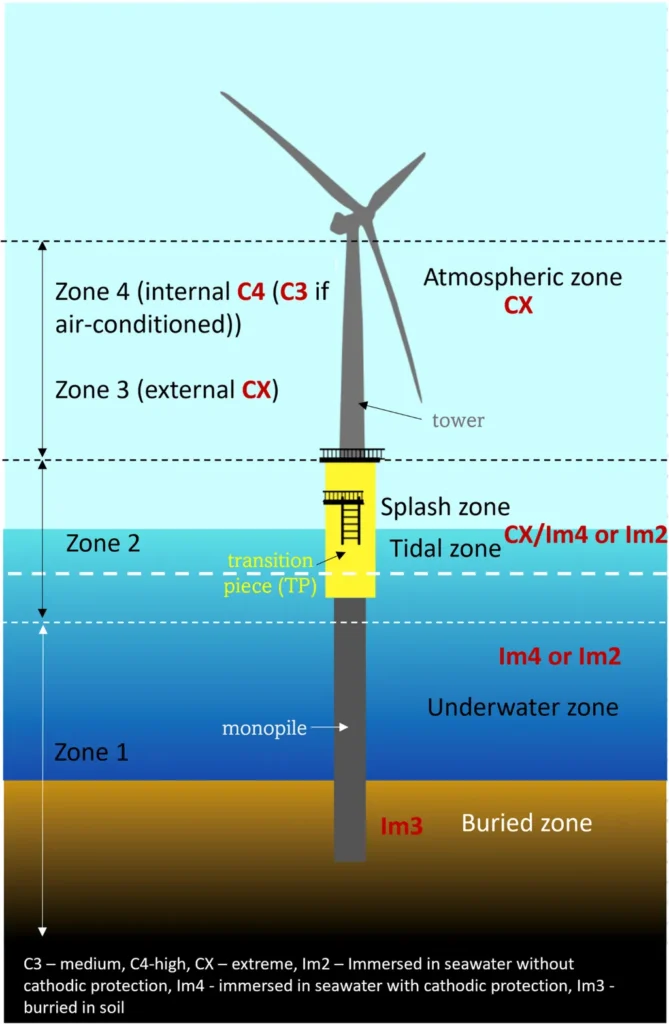

The team, led by Dr. Zhang Yue, subjected S460 steel to a six-month real-sea exposure test in the Sanya sea area, dividing the specimens into four distinct marine zones: atmospheric, splash, tidal, and full immersion. The goal? To understand how each environment affects the steel’s corrosion behavior.

What they found was telling. The splash zone, where waves constantly crash against the structure, proved to be the most corrosive. “The sufficient oxygen in the splash zone was conducive to the formation of Fe3O4 on the specimens,” explained Dr. Zhang. This rust layer, while protective to some extent, indicated a higher corrosion rate in this zone.

Meanwhile, the tidal zone, where structures are periodically submerged and exposed, showed a different story. The persistent electrolyte layer promoted the formation of γ-FeOOH, a different type of rust. Localized corrosion pits were also observed across all zones, with the atmospheric zone showing smaller, densely distributed pits, and the splash zone exhibiting deeper, more pronounced ones.

So, what does this mean for the energy sector? As offshore wind farms continue to expand, understanding the corrosion behavior of materials like S460 steel is crucial. This research could lead to more informed design choices, better maintenance strategies, and ultimately, more durable and efficient offshore structures.

Dr. Zhang and his team’s work is a reminder that even as we push the boundaries of renewable energy, we must also push the boundaries of materials science. After all, the sea is a formidable opponent, and our structures must be ready to face it head-on. As the team continues to delve into the intricacies of marine corrosion, one thing is clear: the future of offshore wind energy is not just about harnessing the power of the sea, but also about understanding and mitigating its corrosive effects.