In the ever-evolving landscape of chemical process industries, maintaining operational safety and product quality is paramount. Traditional fault detection methods, while widely used, often fall short under dynamic conditions, leading to high false alarm rates and missed detections. Enter Oktorifo Gardiola, a researcher from the Department of Chemical Engineering at Universiti Teknologi PETRONAS, who has developed a novel approach to tackle these challenges head-on.

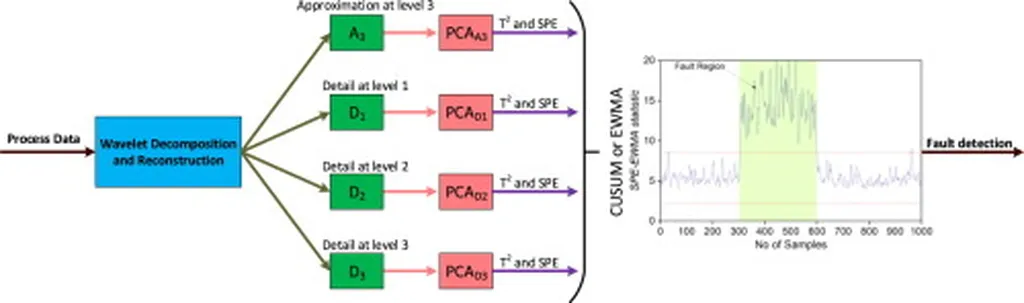

Gardiola’s research, published in the journal *Digital Chemical Engineering*, introduces a Multiscale Recursive Principal Component Analysis (MSRPCA) framework. This innovative method combines multiscale signal decomposition with the adaptive capabilities of Recursive PCA (RPCA). “The idea is to isolate process variations across different frequency bands while continuously updating the PCA model using a moving window mechanism,” Gardiola explains. This real-time adaptability and enhanced noise resistance could be a game-changer for industries grappling with complex, time-varying, and noisy environments.

The study validates the MSRPCA approach using the Tennessee Eastman Process (TEP), a benchmark for chemical process monitoring. The results are promising. For instance, in Fault 16, the missed detection rate in the Hotelling’s T2 chart plummeted from 70.5% using traditional PCA to just 10.5% with MSRPCA. Similarly, the false alarm rate in the Squared Prediction Error chart dropped from 21.3% to 0%. These improvements highlight the robustness and effectiveness of the new method.

For the energy sector, the implications are significant. Chemical processes are the backbone of many energy-related industries, from refining to petrochemical production. Enhanced fault detection means fewer unplanned shutdowns, reduced maintenance costs, and improved overall efficiency. “This research opens up new avenues for adaptive process monitoring,” Gardiola notes. “It’s not just about detecting faults but doing so with greater accuracy and reliability, which is crucial for operational safety and product quality.”

The commercial impact could be substantial. Industries could see a reduction in downtime and an increase in productivity, leading to significant cost savings. Moreover, the ability to adapt to dynamic conditions in real-time could pave the way for more sophisticated and efficient process control systems.

As the energy sector continues to evolve, the need for advanced monitoring techniques will only grow. Gardiola’s research offers a glimpse into the future of fault detection, one that is more adaptive, more accurate, and more reliable. The journey towards smarter, safer, and more efficient chemical processes has taken a significant step forward.