In a significant stride towards enhancing separation technologies, researchers have made notable advancements in polymer inclusion membranes (PIMs), offering promising implications for the energy sector and environmental remediation. A recent review published in the journal *Membranes* (formerly known as *Membranes*) highlights these developments, focusing on improved selectivity, structural integrity, and sustainable fabrication methods.

Led by Anna Nowik-Zając from the Faculty of Science and Technology at Jan Długosz University in Czestochowa, Poland, the research delves into the innovative strategies employed to boost the performance of PIMs. These membranes, which facilitate the selective transport of ions and molecules, are increasingly being utilized in various applications, from heavy metal removal to gas separation.

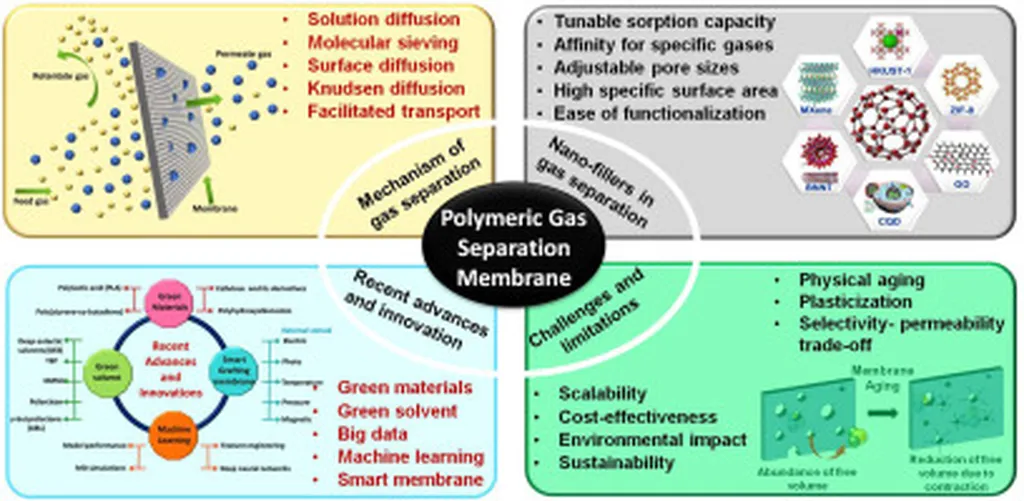

One of the key advancements discussed in the review is the incorporation of novel carriers, such as ionic liquids and task-specific extractants, which enhance the selectivity of PIMs. “By tailoring the chemical composition of these carriers, we can significantly improve the membrane’s ability to distinguish between different ions and molecules,” explains Nowik-Zając. This enhanced selectivity is crucial for applications like carbon dioxide capture, where precise separation is essential for efficiency and cost-effectiveness.

The review also highlights improvements in the mechanical and chemical stability of PIMs. Researchers have achieved this by using high-performance polymers like polyvinylidene fluoride (PVDF) and polyether ether ketone (PEEK), as well as through cross-linking approaches. These enhancements ensure that the membranes can withstand harsh operational conditions, making them more robust and durable for industrial use.

In the realm of environmental applications, PIMs are proving to be highly effective in the removal of heavy metals and organic micropollutants. The review discusses the operational robustness of these membranes, emphasizing their potential for large-scale deployment in water treatment and remediation processes. “The ability of PIMs to selectively remove contaminants from water sources is a game-changer for environmental protection and public health,” notes Nowik-Zając.

Moreover, the integration of PIMs with electrochemical and optical transduction platforms has led to significant advancements in sensor development. These sensors offer improved sensitivity, selectivity, and response time, making them invaluable for real-time monitoring and control in various industrial processes.

The review also explores the growing trend towards sustainable fabrication of PIMs. Researchers are increasingly using biodegradable polymers and green solvents, reducing the environmental impact of membrane production. “Sustainable fabrication methods are not only beneficial for the environment but also align with the growing demand for eco-friendly technologies in the energy sector,” says Nowik-Zając.

Looking ahead, the review identifies several current limitations and proposes future research directions. These include the need for further optimization of membrane performance, the development of scalable manufacturing techniques, and the exploration of new materials and carriers. “Addressing these challenges will be crucial for the widespread adoption of PIM technologies in industrial and environmental sectors,” concludes Nowik-Zając.

As the energy sector continues to seek innovative solutions for efficient separation and purification processes, the advancements in PIMs offer a promising avenue for future developments. With ongoing research and technological advancements, these membranes could play a pivotal role in shaping the future of sustainable energy and environmental protection.