In the quest for safer and more efficient food processing methods, researchers have turned to an unconventional ally: cold plasma. A recent study published in the journal *Future Foods* sheds light on how this emerging technology impacts the nutritional and biochemical characteristics of pistachios, offering promising insights for the food and energy sectors.

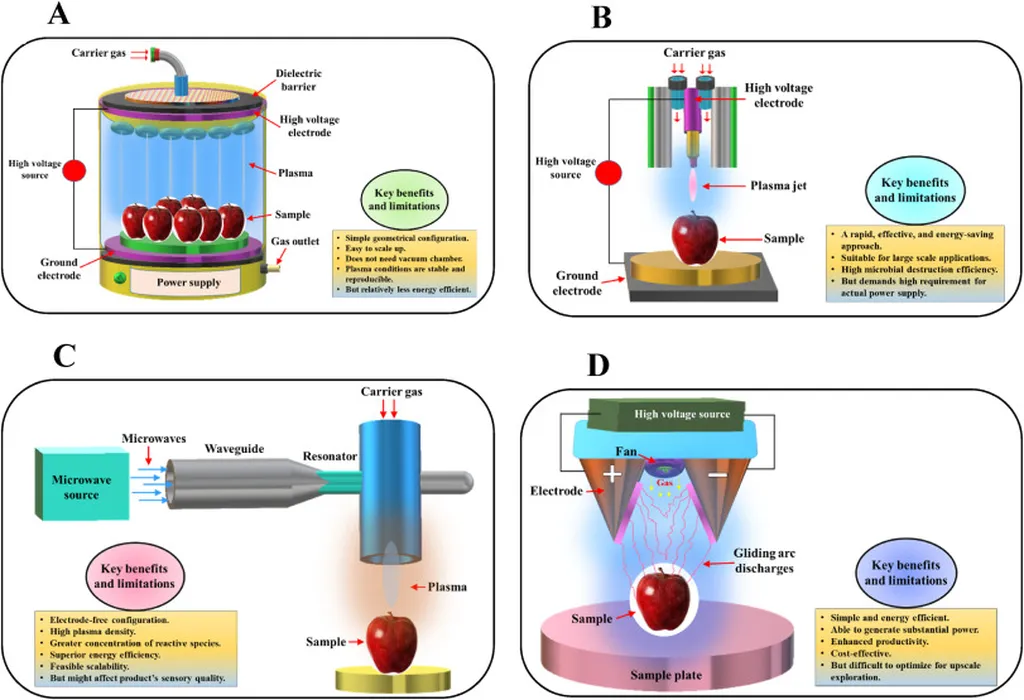

Led by Mahdiyeh Bakhtiyari-Ramezani from the Plasma Physics and Nuclear Fusion Research School at the Nuclear Science and Technology Research Institute (NSTRI) in Tehran, Iran, the study explores the effects of dielectric barrier discharge (DBD) plasma on pistachios. Cold plasma, a partially ionized gas, has gained attention for its ability to decontaminate food surfaces without significant heat, making it an attractive option for the food industry.

The research team subjected pistachios to plasma treatment for varying durations—5, 10, 20, and 40 minutes—to assess changes in nutritional and biochemical properties. The results were mixed but revealing. “We found that short exposure times, up to 10 minutes, did not significantly alter the nutritional content of pistachios,” Bakhtiyari-Ramezani explained. “However, prolonged exposure had notable effects.”

For instance, the study observed a significant decrease in linoleic acid—a healthy unsaturated fat—and an increase in palmitic acid—a saturated fat—after 40 minutes of treatment. Additionally, longer exposure times led to a reduction in protein and carbohydrate content, with protein levels dropping by up to 14.56% and carbohydrates by up to 44.0%. “This suggests that plasma treatment time is a critical factor in nut processing,” Bakhtiyari-Ramezani noted.

The findings have significant implications for the food industry, particularly for companies looking to adopt plasma technology for decontamination and preservation. While short plasma treatments appear to preserve the nutritional integrity of pistachios, longer exposures could compromise their health benefits. This balance is crucial for manufacturers aiming to meet consumer demands for both safety and nutritional value.

From an energy perspective, the study highlights the potential for plasma technology to reduce reliance on traditional, energy-intensive food processing methods. As the world seeks more sustainable and efficient solutions, cold plasma could emerge as a key player in the energy sector, offering a greener alternative for food processing.

The research also underscores the need for further optimization. “Future studies should focus on improving device design and optimizing treatment duration to mitigate risks and ensure food safety,” Bakhtiyari-Ramezani said. This could pave the way for more widespread adoption of plasma technology in the food industry, benefiting both producers and consumers.

As the field of cold plasma continues to evolve, this study serves as a reminder of the delicate balance between innovation and preservation. By carefully calibrating treatment times and refining technology, the food and energy sectors can harness the full potential of plasma processing, ensuring safer, more sustainable, and nutritionally sound food products for the future.