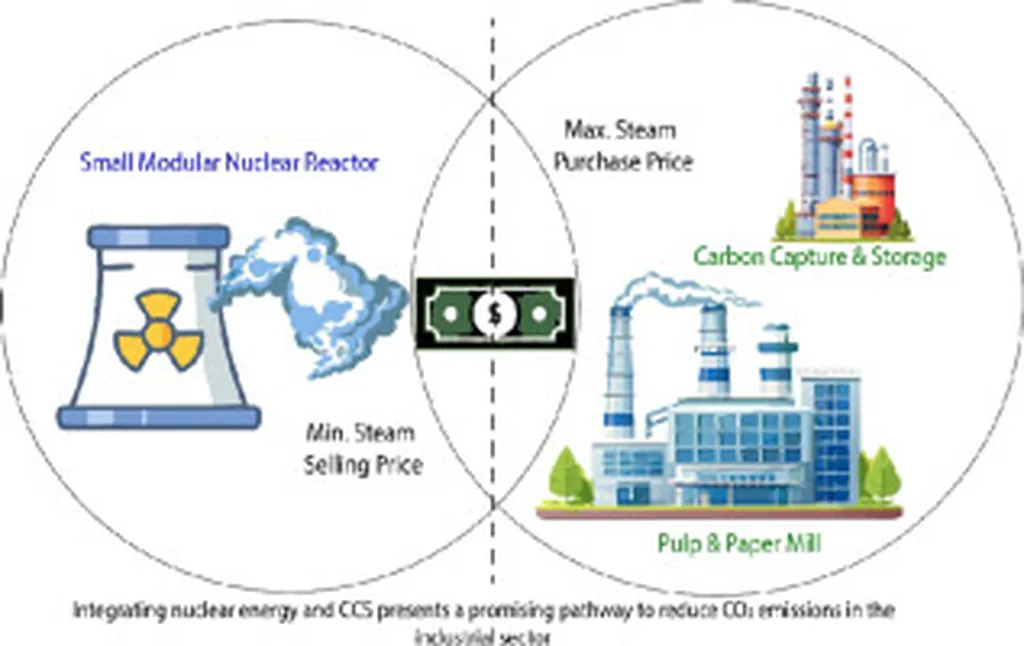

In a groundbreaking study published in the journal *Carbon Capture Science & Technology*, researchers have explored a novel approach to slash carbon emissions in the pulp and paper industry by integrating nuclear energy with carbon capture and storage (CCS) technologies. The study, led by Edgar Carrejo from the Department of Forest Biomaterials at North Carolina State University, offers a compelling look at how small modular nuclear reactors (SMNRs) could power CCS systems, potentially revolutionizing the industry’s environmental footprint.

The pulp and paper sector is a significant contributor to CO2 emissions, ranking among the top three industry sectors in the United States when biogenic CO2 is included. Traditional CCS technologies, such as amine-based capture, are energy-intensive, often relying on fossil fuels that undermine their environmental benefits. Carrejo’s research proposes a paradigm shift by using nuclear energy to power these CCS systems, eliminating point source emissions and drastically reducing the industry’s carbon footprint.

The study evaluated the economic feasibility of integrating SMNRs with CCS in three types of pulp and paper mills in the southeastern United States: a bleached softwood kraft mill, an unbleached softwood kraft mill, and a recycling mill. The findings were striking. For the bleached softwood kraft mill, two 200 MW-thermal SMNRs were sufficient to cover the demand for steam and power, while one module was enough for the other mill types. “Nuclear heat integration into a CCS system can decrease CO2 emissions by up to 91% in a typical kraft paper mill, with the remaining emissions being primarily biogenic,” Carrejo explained. For recycling mills, the potential is even more promising, with the possibility of achieving almost zero emissions.

The economic analysis revealed that integrating high-pressure nuclear steam into the mill’s existing combined heat and power (CHP) system to replace natural gas boilers could significantly lower CO2 capture costs. However, for nuclear steam to be competitive with natural gas, it would need to cost a maximum of approximately $16 per metric ton, which is roughly half the expected levelized cost of heat from a nuclear power plant. Despite this cost discrepancy, the study highlights the potential of SMNRs to help the pulp and paper industry reduce CO2 emissions substantially.

The implications of this research extend beyond the pulp and paper industry. As the world seeks innovative solutions to combat climate change, the integration of nuclear energy with CCS technologies could pave the way for similar applications in other energy-intensive industries. “This study demonstrates that integrating CCS and SMNRs can help the pulp and paper industry reduce CO2 emissions, even if the cost is not yet competitive with other fuel options,” Carrejo noted. The findings could spur further research and development in nuclear energy and CCS technologies, driving down costs and making them more viable for widespread adoption.

As the energy sector continues to evolve, the synergy between nuclear energy and CCS technologies could play a pivotal role in achieving global decarbonization goals. Carrejo’s research offers a glimpse into a future where industries can operate sustainably, reducing their environmental impact without compromising on productivity or economic viability. The journey towards a low-carbon future is complex, but studies like this one bring us one step closer to realizing that vision.