In the quest to mitigate the environmental footprint of one of the world’s most polluting industries, researchers are turning to Life Cycle Assessment (LCA) as a powerful tool for quantifying and managing emissions. A recent review published in the journal *Systems* (formerly known as *Systems, Systems Engineering and Information Technology*) synthesizes the latest advancements in LCA methodology, offering critical insights into the cement industry’s environmental impacts and potential pathways for reduction. Led by Qiang Su of Tongji University in Shanghai, the research underscores the urgent need for data-driven strategies to curb emissions in a sector that contributes significantly to global carbon outputs.

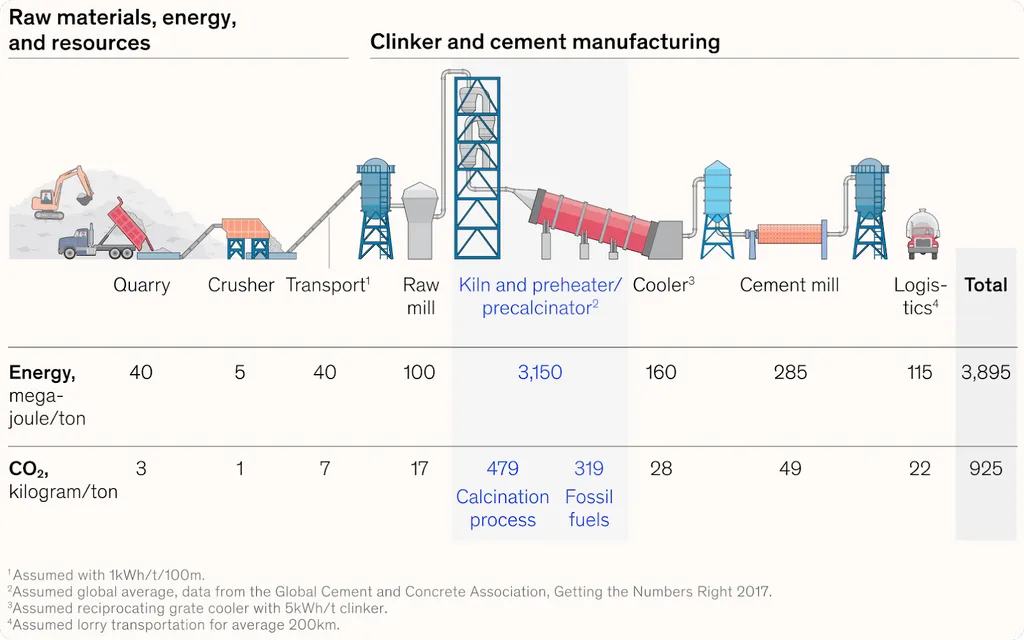

The cement industry is responsible for approximately 8% of global CO₂ emissions, a staggering figure that underscores the need for innovative solutions. Su and his team delve into the core phases of LCA—goal and scope definition, inventory analysis, impact assessment, and interpretation—to provide a comprehensive overview of how these assessments can inform policy and industry practices. “LCA is not just about measuring emissions; it’s about understanding the full environmental load of cement production and identifying where reductions can be made most effectively,” Su explains. This approach is particularly relevant as the industry grapples with the dual challenges of meeting growing demand and reducing its environmental impact.

One of the study’s key findings is the significant variation in emissions across different regions, with China, as the world’s largest cement producer, playing a pivotal role. The research highlights that cradle-to-gate emissions typically range from 0.9 to 1.0 tons of CO₂ per ton of cement produced. However, alternative cement types, such as limestone calcined clay cements, offer promising reductions of around 30–45% in emissions. These alternatives could be game-changers for the industry, providing a pathway to lower carbon footprints without compromising on quality or performance.

The review also examines technological innovations, such as carbon capture technologies, which have the potential to cut plant emissions by up to 90%. Material substitutions and other environmental load reduction strategies are quantitatively assessed, offering a roadmap for manufacturers looking to adopt more sustainable practices. “The integration of LCA into policy frameworks, such as emissions trading schemes, is crucial for driving industry-wide change,” Su notes. By quantifying the environmental impacts of different production methods, LCA can guide sustainability certifications and inform regulatory decisions, ultimately shaping a more sustainable future for the cement industry.

Despite these advancements, the research identifies persistent methodological challenges, including data quality issues, scope limitations, and the limited real-world integration of LCA findings. Addressing these challenges will be key to ensuring that LCA-driven strategies are effectively implemented. The study calls for the development of country-specific Life Cycle Inventory (LCI) databases, the integration of techno-economic assessments into LCA frameworks, and the creation of user-friendly digital tools to enhance the practical application of these assessments.

As the energy sector increasingly focuses on decarbonization, the insights from this research could shape future developments in the cement industry. By providing a clear, data-driven approach to emissions accounting and reduction, LCA offers a powerful tool for manufacturers, policymakers, and investors alike. The findings underscore the need for continued innovation and collaboration to achieve a more sustainable future for one of the world’s most critical industries.