In the quest for sustainable and scalable production of phycocyanin, a valuable blue pigment derived from cyanobacteria, researchers have turned to an unconventional source: halo-alkaliphilic cyanobacteria found in alkaline soda lakes. A recent study published in the journal *Frontiers in Microbiology* outlines a novel bioprocess that could revolutionize the industry, with significant implications for the energy sector.

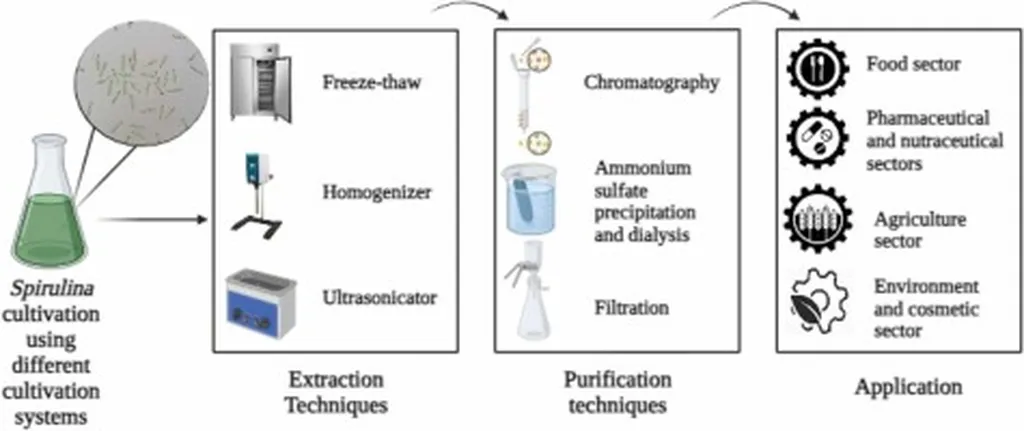

Phycocyanin, primarily sourced from the cyanobacterium Limnospira platensis, commonly known as Spirulina, has long been valued for its use in food colorants, cosmetics, and even as a potential therapeutic agent. However, traditional production methods face substantial challenges, including high water consumption, carbon dioxide emissions, and operational instability. These issues have hindered the widespread adoption of phycocyanin in commercial applications.

Lead author Lianchun Yi, from the Department of Earth, Energy, and Environment at the University of Calgary, and his team have proposed a series of innovations that address these sustainability concerns. “Our goal was to develop a bioprocess that not only reduces environmental impact but also enhances the stability and scalability of phycocyanin production,” Yi explained.

The researchers identified four key innovations to achieve this goal. First, they utilized a pH level above 10.5 to implement direct air capture of carbon dioxide, significantly reducing emissions associated with traditional production methods. “By leveraging the natural alkalinity of these environments, we can capture CO2 directly from the air, making the process more sustainable,” Yi noted.

Second, the team employed a consortium of an alkaliphilic cyanobacterium and its associated heterotrophs, which improved process stability by creating a more resilient microbial community. This approach ensures that the production process remains robust and less susceptible to disruptions.

Third, the researchers introduced passive fermentation for phycocyanin extraction, drastically reducing water needs. This method not only conserves water but also simplifies the extraction process, making it more efficient and cost-effective.

Finally, the team integrated anaerobic digestion to recover energy and recycle carbon dioxide and nutrients. This closed-loop system ensures that resources are used efficiently, aligning with the principles of a circular bioeconomy.

While these innovations present a promising solution, challenges remain. For instance, water losses associated with direct air capture of carbon dioxide are still high, and nutrient recycling is only partially successful. However, the potential benefits of this bioprocess are substantial. “This approach could offer a scalable, more sustainable alternative to conventional phycocyanin production, with significant implications for the energy sector,” Yi said.

The study’s findings were published in the journal *Frontiers in Microbiology*, a leading publication in the field of microbiology. The research highlights the potential for integrating innovative bioprocesses to achieve sustainability goals in the production of high-value bioproducts.

As the world continues to seek sustainable solutions to meet growing demands, this research offers a glimpse into the future of biorefineries and the circular bioeconomy. By addressing the challenges of phycocyanin production, Yi and his team have paved the way for more environmentally friendly and economically viable production methods, with far-reaching implications for the energy sector and beyond.