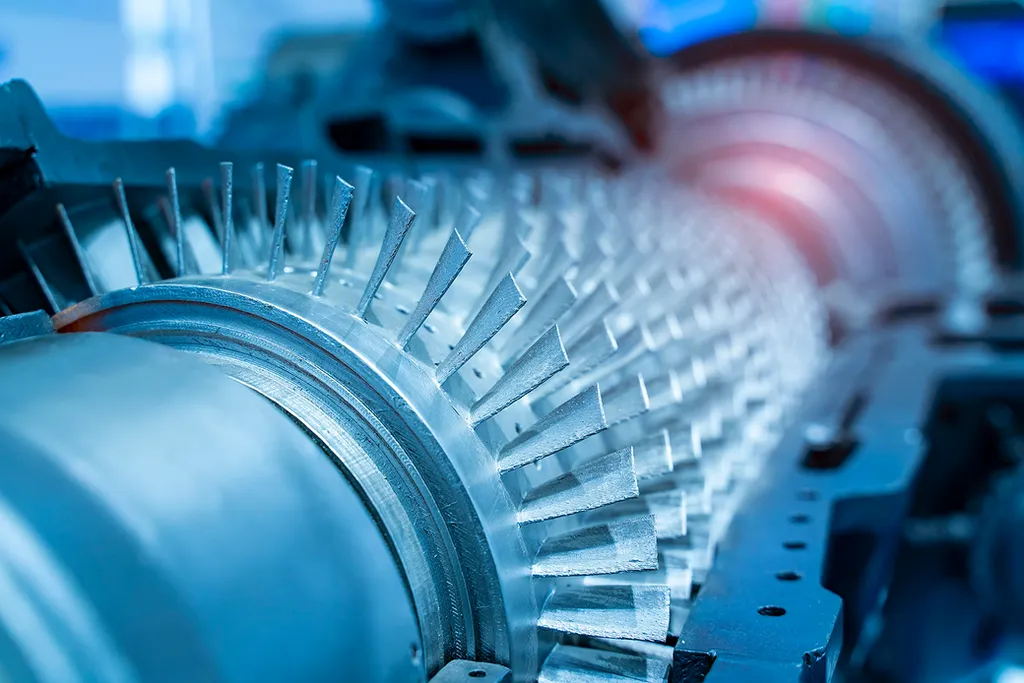

In the quest for cleaner energy solutions, researchers are turning to innovative fuel blends to power gas turbines, and a recent study is shedding light on the potential and challenges of these alternatives. Amr Abbass, a researcher from the Department of Mechanical Engineering at Mississippi State University, has led a comparative analysis of hydrogen, ammonia-hydrogen blends, and conventional Jet-A2 fuel in gas turbine combustors. The findings, published in the journal “Case Studies in Thermal Engineering,” offer valuable insights for the energy sector as it navigates the transition to low-carbon technologies.

The study employs a well-stirred reactor model and a validated MATLAB library called H2ools to evaluate various performance metrics, including flame temperature, pollutant generation, combustion stability, and thermal efficiency. This approach addresses a critical gap in existing research, which often lacks standardized comparisons relevant to gas turbines.

One of the key findings is that pure hydrogen achieves the highest adiabatic flame temperature (2552 K) and laminar flame speed (7.73 m/s), making it an attractive option for high-efficiency combustion. However, it also results in increased nitrogen oxide (NOx) emissions, a significant environmental concern. “Hydrogen generates the minimal NOx emissions per unit of energy output—approximately 0.1 g per kilowatt-hour at a residence time of 5 ms,” notes Abbass. This suggests that while hydrogen is highly efficient, managing its emissions will be crucial for its widespread adoption.

On the other hand, Jet-A2, the conventional jet fuel, exhibits lower flame temperatures (2429 K) and minimal NOx emissions (1308 parts per million). The study also examines a 50% ammonia-hydrogen blend, which yields the highest NOx output (7022 parts per million) due to the nitrogen content in ammonia. This highlights the trade-offs between using ammonia as a carbon-free fuel and its potential to increase NOx emissions.

The research integrates reactor-level studies with high-fidelity modeling tools, providing a comprehensive framework for understanding the behavior of these fuels in gas turbine combustors. This information is invaluable for engineers and policymakers working on combustor design, fuel selection, and emissions control strategies.

The implications of this study extend beyond the laboratory. As the energy sector seeks to reduce its carbon footprint, the findings offer a roadmap for integrating new zero-carbon fuels into existing infrastructure. “This study provides insights for combustor design, fuel selection, and emissions control strategies in low-carbon aircraft and power systems,” Abbass explains. By understanding the performance and environmental impacts of these fuel blends, industries can make informed decisions that balance efficiency, cost, and sustainability.

The study’s publication in “Case Studies in Thermal Engineering” underscores its relevance to both academic and industrial audiences. As the energy sector continues to evolve, research like this will be instrumental in shaping the future of low-carbon technologies. The findings not only highlight the potential of hydrogen and ammonia-hydrogen blends but also underscore the need for continued innovation and adaptation in the pursuit of a cleaner energy future.