In the realm of wind energy, a team of researchers from DNV, a global quality assurance and risk management company, has been working to improve the accuracy of wake models used to predict wind farm performance. The researchers, Diego Siguenza-Alvarado, Matthew Harrison, Mohammadreza Mohammadi, Pragya Vishwakarma, Ervin Bossanyi, Lars Landberg, and Majid Bastankhah, have conducted a study that assesses the performance of engineering wake models under real-world operational conditions.

The study, published in the journal Wind Energy Science, utilized a unique dataset from the Lillgrund offshore wind farm, collected during the Horizon 2020 TotalControl project. This dataset combined synchronous SCADA (Supervisory Control and Data Acquisition) and LiDAR (Light Detection and Ranging) measurements, both under normal operating conditions and during active wake steering, a technique used to optimize wind farm performance by intentionally misaligning turbines.

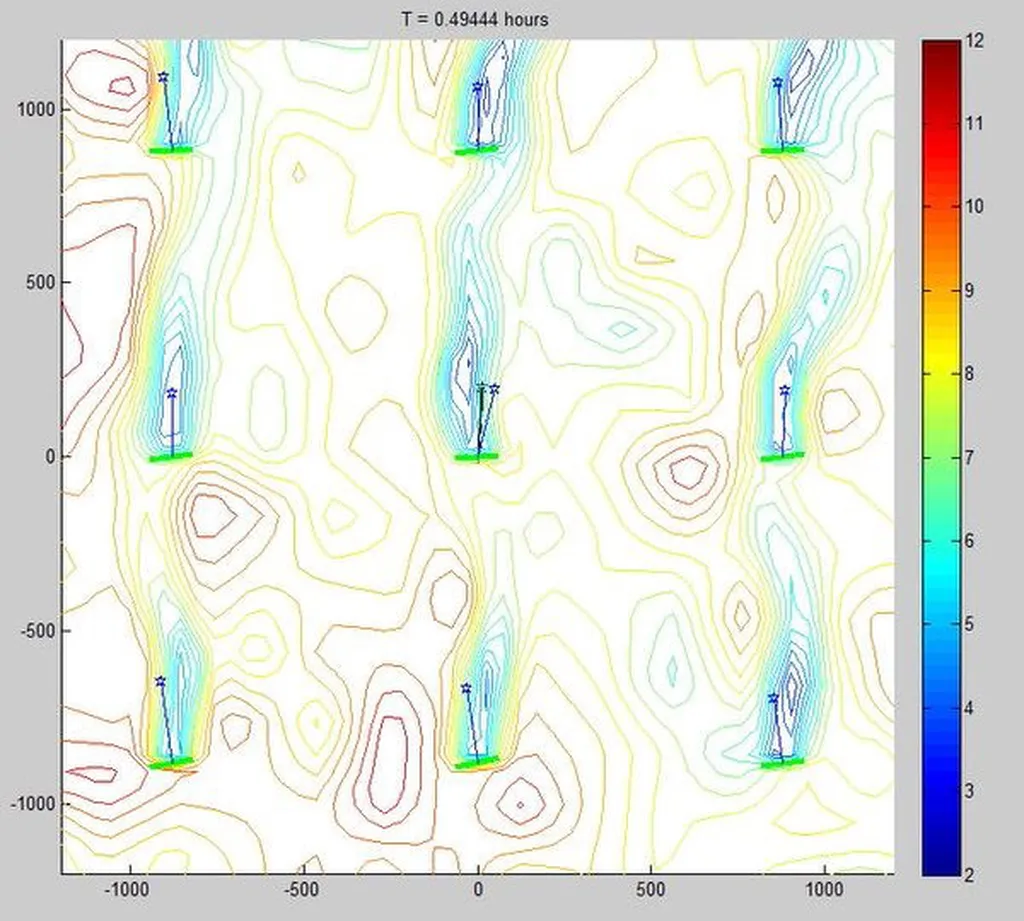

The researchers assessed four different analytical wake model combinations, each employing different formulations for velocity deficit, added turbulence, wake superposition, and deflection. These models were implemented in the LongSim software developed by DNV. The analysis focused on time-averaged wake velocity deficits and turbine- and farm-level power output, with model accuracy quantified using mean absolute error metrics.

The results showed that the models were able to reproduce general wake deficit trends and wake deflection across a range of atmospheric conditions. The normalized velocity deficit errors ranged between 7% and 15%. However, power prediction errors increased with farm depth, with turbine-level errors between 3% and 23% and farm-level errors between -13% and +30%.

The study found that some analytical models achieved accuracy comparable to reported Large Eddy Simulation (LES) results while requiring substantially lower computational cost. This highlights the value of field campaigns for benchmarking engineering wake models and informs trade-offs between model fidelity and operational practicality for wake steering applications.

For the energy industry, this research is significant as it provides a more accurate and cost-effective way to predict wind farm performance. This can lead to improved wind farm design and operation, ultimately increasing energy output and reducing costs. The use of active wake steering, as demonstrated in this study, can also help to optimize wind farm performance and increase energy production.

This article is based on research available at arXiv.