The SMARTLINE-PV project, funded by the European Union’s Horizon Europe program, is setting out to revolutionise the photovoltaic (PV) sector by developing scalable, environmentally friendly tin-based perovskite solar cells. This initiative directly addresses two critical challenges in the PV industry: lead toxicity and the need for improved crystallisation processes.

Photovoltaic solar energy conversion is pivotal to Europe’s transition towards a clean, resilient, and climate-neutral energy system. While silicon solar modules currently dominate the market, their rigidity, weight, and limited design flexibility restrict their use in many emerging applications. Next-generation thin-film photovoltaic technologies, particularly perovskite solar cells, offer a promising alternative. These cells enable solar energy generation in areas where conventional photovoltaics are less suitable. Perovskite solar cells have garnered significant attention over the past decade due to their rapid rise in power conversion efficiency, now exceeding 27%, combined with low-temperature processing and compatibility with flexible substrates.

However, high-performance perovskite solar cells contain lead, which raises environmental and societal concerns and could hinder large-scale deployment. The SMARTLINE-PV project aims to tackle this challenge by developing scalable, tin halide perovskite solar cells with a focus on innovative crystallisation technologies. By combining material innovation, plasma-assisted processing, ecodesign, and application-driven demonstrators, the project aims to unlock new areas of application, particularly in the rapidly growing fields of Internet of Things (IoT) devices and Building-Integrated Photovoltaics (BIPV).

A strong European consortium is driving this innovation. The project brings together a multidisciplinary team of 13 partners from across Europe, including academic and applied research expertise, and industrial know-how. Universities and research organisations are leading the development of advanced tin perovskite materials, crystallisation chemistry, device architectures, module integration, sustainability assessment, and circularity. Industrial partners are focusing on scalable processing, roll-to-roll compatibility, and market-oriented design. This collaboration enables SMARTLINE-PV to bridge the gap between fundamental materials research and industrially relevant photovoltaic solutions.

Replacing lead with tin in perovskite solar cells is a promising route towards environmentally friendly photovoltaics. Tin halide perovskites share many favourable optoelectronic properties with their lead-based counterparts, including strong light absorption and excellent charge transport. Tin-based perovskite solar cells have already demonstrated efficiencies exceeding 17%. However, several critical challenges remain, such as fast crystallisation, high defect densities, and chemical instability due to the oxidation of Sn2+ to Sn4+. These factors negatively impact device efficiency, reproducibility, long-term stability, and large-area fabrication. SMARTLINE-PV addresses these issues through novel precursor chemistry and crystallisation control strategies.

Innovative crystallisation mediators are designed to slow down the crystal formation process, allowing tin perovskite films to grow with fewer defects and improved structural uniformity. The project also explores non-oxidising solvents, hydrogen-bond interactions, and halide-halide interactions to stabilise the tin oxidation state and further improve film quality. These material innovations lay the foundation for high-performance, stable tin halide perovskite solar cells suitable for both laboratory demonstrations and industrially relevant manufacturing.

Conventional perovskite fabrication often relies on anti-solvent dripping, a process that is difficult to control, solvent-intensive, and not well suited for large-area or roll-to-roll production. In contrast, the plasma-assisted approach investigated in SMARTLINE-PV enables fast, solvent-free crystallisation at low temperatures, offering good control over nucleation and crystal growth. By combining optimised precursor formulations with carefully tuned plasma conditions, uniform and high-quality perovskite films can be produced without anti-solvents. This process is also well compatible with roll-to-roll (R2R) manufacturing, enabling continuous deposition on large-area flexible substrates. This compatibility represents an important step toward industrial scalability, reduced energy consumption, and lower production costs.

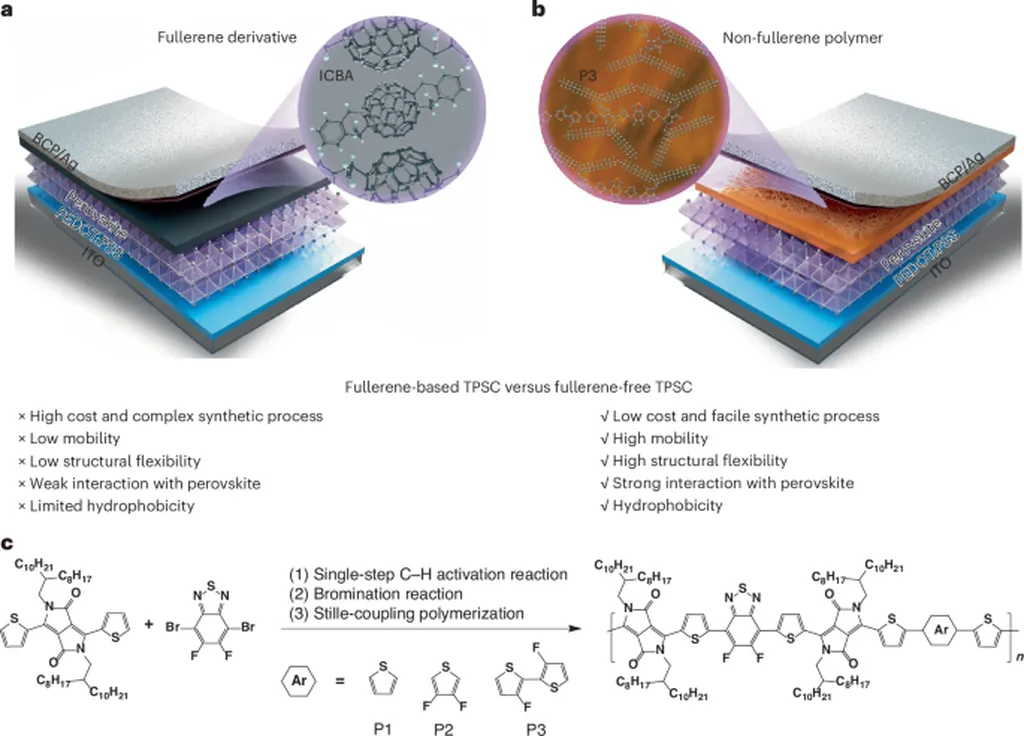

In addition to optimising the perovskite absorber, SMARTLINE-PV focuses on customising the device architecture specifically for tin perovskites. Tailored interlayers are developed to enhance charge extraction, suppress recombination losses, and protect sensitive interfaces within the solar cell stack. Novel device architectures are explored to improve mechanical flexibility and long-term operational stability under real-world conditions. Through this integrated approach, SMARTLINE-PV aims to achieve efficiencies above 20% for tin-based perovskite solar cells, an ambitious but realistic target that would highlight the potential of this solar cell technology as a viable alternative to established thin-film technologies.

In the built environment, solar energy systems are expected to combine performance with design and functionality. SMARTLINE-PV addresses this by enabling colour variation in tin perovskite solar cell modules through the MorphoColor concept, which is inspired by the structural colouration found in butterfly wings. The MorphoColor concept relies on photonic structures that combine geometrically patterned substrates with interference layers