Researchers from Delft University of Technology and Ulsan National Institute of Science and Technology have made significant strides in optimizing molybdenum disulfide (MoS₂) for use in hydrogen production. Their work, published in the journal Advanced Materials, focuses on controlling the properties of MoS₂ to enhance its performance in the hydrogen evolution reaction (HER), a key process in producing hydrogen fuel.

Molybdenum disulfide is a promising material for catalysis due to its unique layered structure and electronic properties. However, its effectiveness in the HER is influenced by factors such as crystallinity, defect density, and electrical conductivity. The researchers employed molecular beam epitaxy (MBE), a precise thin-film deposition technique, to grow MoS₂ directly on silicon substrates. This method allows for fine-tuning of the material’s properties by varying parameters like annealing temperature, deposition cycle number, and the ratio of molybdenum to sulfur.

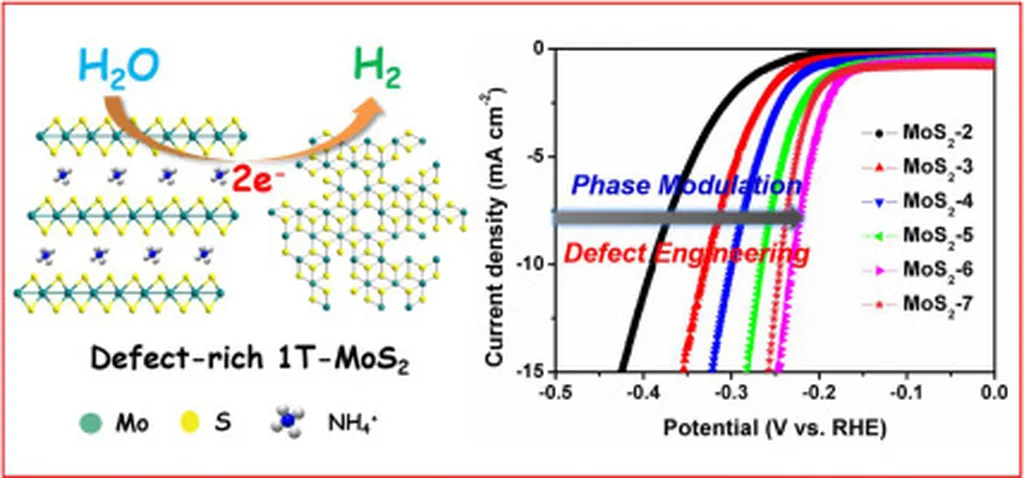

The study found that higher annealing temperatures and excessive deposition cycles improve the crystallinity of MoS₂ but reduce the density of active edge sites and electrical conductivity, leading to poorer HER performance. Conversely, intermediate cycle numbers and sulfur-deficient conditions resulted in heterostructures with residual metallic molybdenum and sulfur vacancies. These defects activate the otherwise inert basal planes of MoS₂ and provide conductive pathways, significantly enhancing catalytic activity.

The optimized MoS₂ films achieved remarkable performance metrics, including low overpotentials, large electrochemical surface areas, and high turnover frequencies. These findings highlight the importance of defect engineering in MoS₂ and provide a strategy for designing more efficient catalysts for hydrogen production.

For the energy industry, this research offers a pathway to develop more effective and integrated catalytic systems for hydrogen generation. By controlling the growth conditions of MoS₂, it is possible to create catalysts that are both highly active and compatible with semiconductor technologies, paving the way for advanced energy solutions.

This article is based on research available at arXiv.