Researchers Xinyu Jia, Iason Papaioannou, and Daniel Straub from the University of Texas at Austin have developed a new approach to predictive maintenance that could help energy companies better manage their equipment and reduce downtime. Their work, published in the journal IEEE Transactions on Reliability, focuses on improving the accuracy of predictions about when equipment will fail, a process known as prognostics and health management (PHM).

In the energy industry, maintaining equipment like wind turbines, solar panels, and power plant machinery is crucial for ensuring reliable and efficient operation. Predictive maintenance, which uses data to anticipate when equipment will need servicing or replacement, can help companies save money and prevent unexpected failures. However, current methods often rely solely on data from the specific piece of equipment being monitored, ignoring valuable information from similar systems.

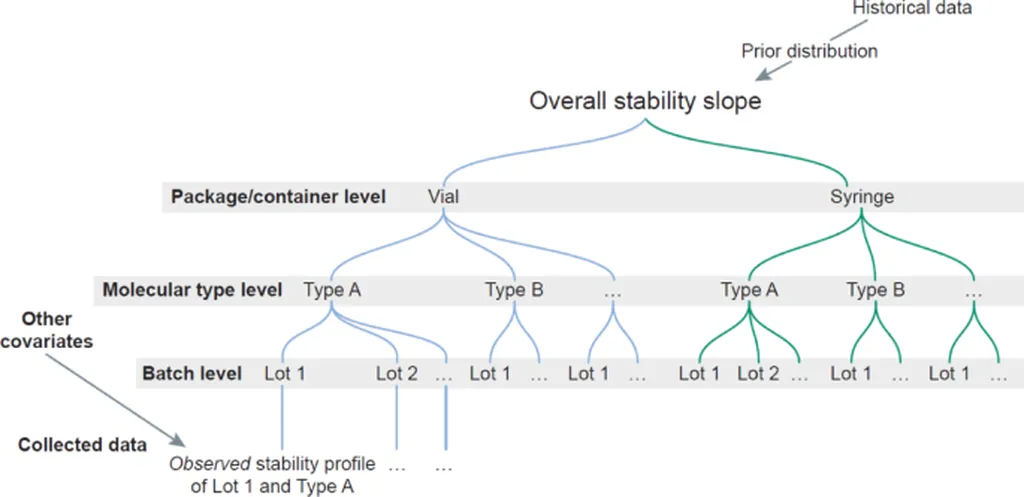

The researchers propose a new framework called hierarchical Bayesian modeling (HBM) that integrates data from both the equipment being monitored and similar systems. This approach uses statistical techniques to learn from the collective experience of similar equipment, improving the accuracy of predictions about when a particular piece of equipment will fail. The framework also allows for continuous updates as new data becomes available, leading to increasingly accurate assessments over time.

The researchers tested their framework on two real-world applications: predicting crack growth in materials and assessing the degradation of lithium batteries. In both cases, the HBM framework significantly improved the accuracy of remaining useful life (RUL) predictions compared to traditional methods. The framework also provided a way to manage uncertainty in these predictions, which is crucial for making informed maintenance decisions.

For the energy industry, this research offers a promising new tool for predictive maintenance. By leveraging data from similar equipment, energy companies can improve the accuracy of their failure predictions and make more informed decisions about maintenance and replacement. This could lead to significant cost savings and improved reliability for energy systems. The research was published in the IEEE Transactions on Reliability, a peer-reviewed journal focused on reliability, maintainability, and quality control of products and systems.

This article is based on research available at arXiv.