Researchers from the University of Nebraska-Lincoln, led by Yu Wang and Shanglu Yang, have published a study in the Journal of Laser Applications that explores a novel approach to laser welding, which could have significant implications for the energy sector, particularly in the manufacturing of advanced optoelectronic devices and precision engineering components.

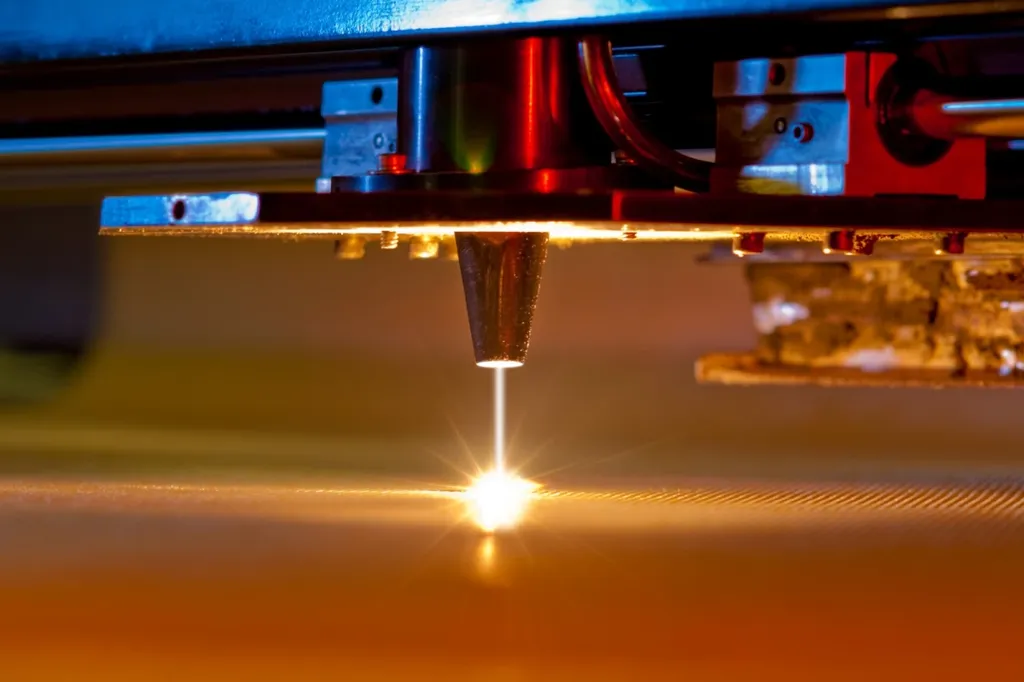

The study focuses on ultrafast laser welding, a technique that offers high precision for integrating transparent and metallic materials. However, its practical application has been limited by the challenge of precisely controlling the interfacial gap between materials. To address this, the researchers introduced a polymer interlayer between naturally stacked samples of sapphire and Fe-36Ni alloy to create a variable interfacial gap. This allowed them to systematically evaluate how different gap sizes affect the morphology, melting behavior, and elemental transport during the welding process.

The researchers employed a burst mode ultrafast laser, which redistributes pulse energy into sequential sub-pulses. This approach enhances plasma-material coupling and stable thermal accumulation, leading to more effective welding. Compared to single pulse irradiation, the burst mode sustained continuous bonding across gaps exceeding 10 micrometers—far beyond the failure threshold of single pulse mode—and formed a fusion zone 82% larger.

The study’s findings are significant for the energy industry, particularly in the manufacturing of components that require precise integration of transparent and metallic materials. For instance, this technique could be applied in the production of advanced solar panels, where efficient light management is crucial. The ability to weld materials with larger gaps and achieve stronger bonds could also improve the durability and performance of various energy-related devices, from sensors to high-precision optical components.

In conclusion, the research provides a scientific basis for high-gap-tolerance ultrafast laser welding, offering a promising approach for scalable integration of transparent-metal hybrid components in advanced optoelectronic and precision engineering applications within the energy sector.

Source: Journal of Laser Applications

This article is based on research available at arXiv.