This week, the clean hydrogen sector took a decisive step toward pragmatism with the advancement of turquoise hydrogen reactors—innovative systems that catalytically convert methane into hydrogen and solid elemental carbon, rather than carbon dioxide. Spearheaded by start-ups like Etch Materials and multinationals such as Huntsman, these reactors promise to slash overall costs and open new income streams, positioning turquoise hydrogen as a viable bridge between today’s fossil fuel dependence and tomorrow’s green hydrogen economy.

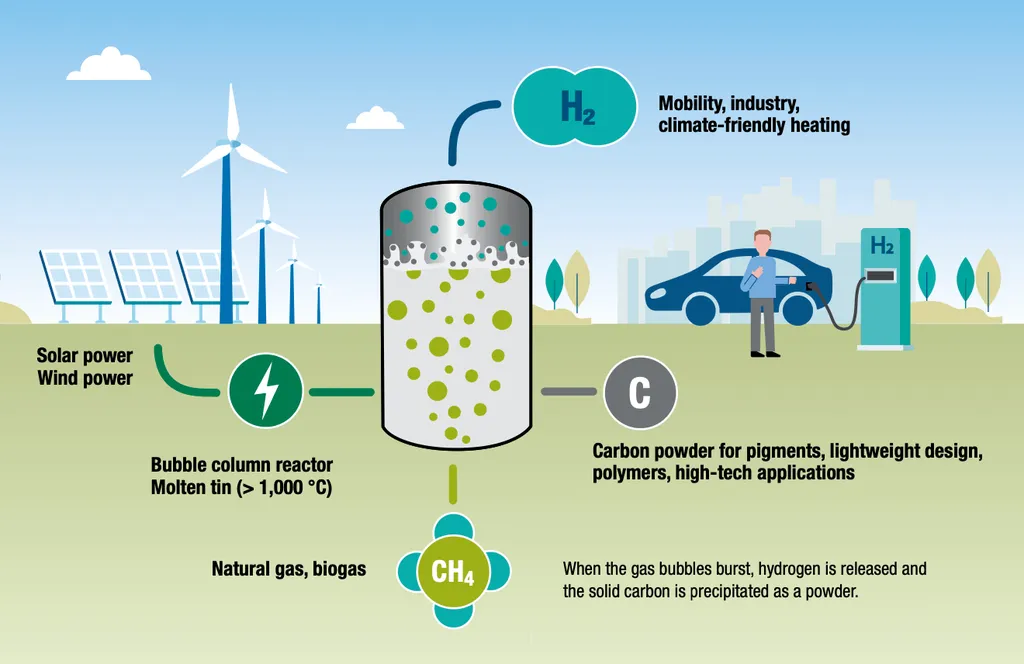

The technology’s core innovation lies in its ability to produce hydrogen from methane without releasing CO₂, instead yielding solid carbon—a valuable byproduct for industrial applications. This contrasts sharply with conventional “blue” hydrogen, which relies on carbon capture and storage (CCS) to mitigate emissions, a process that remains energy-intensive and geographically constrained. Turquoise hydrogen reactors, by avoiding the need for CCS infrastructure, could dramatically reduce both capital and operational expenditures, making them particularly attractive in regions where CCS deployment is impractical or uneconomical.

Industry analysts are quick to note that 2026 is shaping up to be a watershed year for hydrogen pragmatism. “The clean hydrogen sector is neither collapsing nor taking off in 2026,” says François Le Scornet, an analyst at Carbonexit Consulting. “We will see a shift to the most realistic set of projects that target ammonia, refinery hydrogen replacement, and a handful of early direct-reduced iron steel units.” This sentiment is echoed in the latest revision of the EU’s sustainable fuel mandates, which now explicitly support “renewable fuels of non-biological origin,” including hydrogen-derived ammonia and hydrocarbon fuels.

The implications for energy sustainability are profound. Turquoise hydrogen could accelerate the decarbonization of heavy industry, shipping, and aviation—sectors where electrification remains a distant prospect. By offering a lower-cost, lower-risk pathway to hydrogen production, these reactors may also help bridge the gap until green hydrogen, produced via electrolysis powered by renewable energy, achieves full cost parity. Moreover, the solid carbon byproduct could find use in everything from construction materials to advanced manufacturing, further enhancing the technology’s economic appeal.

As the global energy transition gathers pace, turquoise hydrogen reactors represent a critical step forward: a pragmatic, scalable solution that balances environmental imperatives with economic realities. Their success could redefine the hydrogen landscape, making clean fuel production more accessible and accelerating the shift away from fossil fuels across the hardest-to-abate sectors.