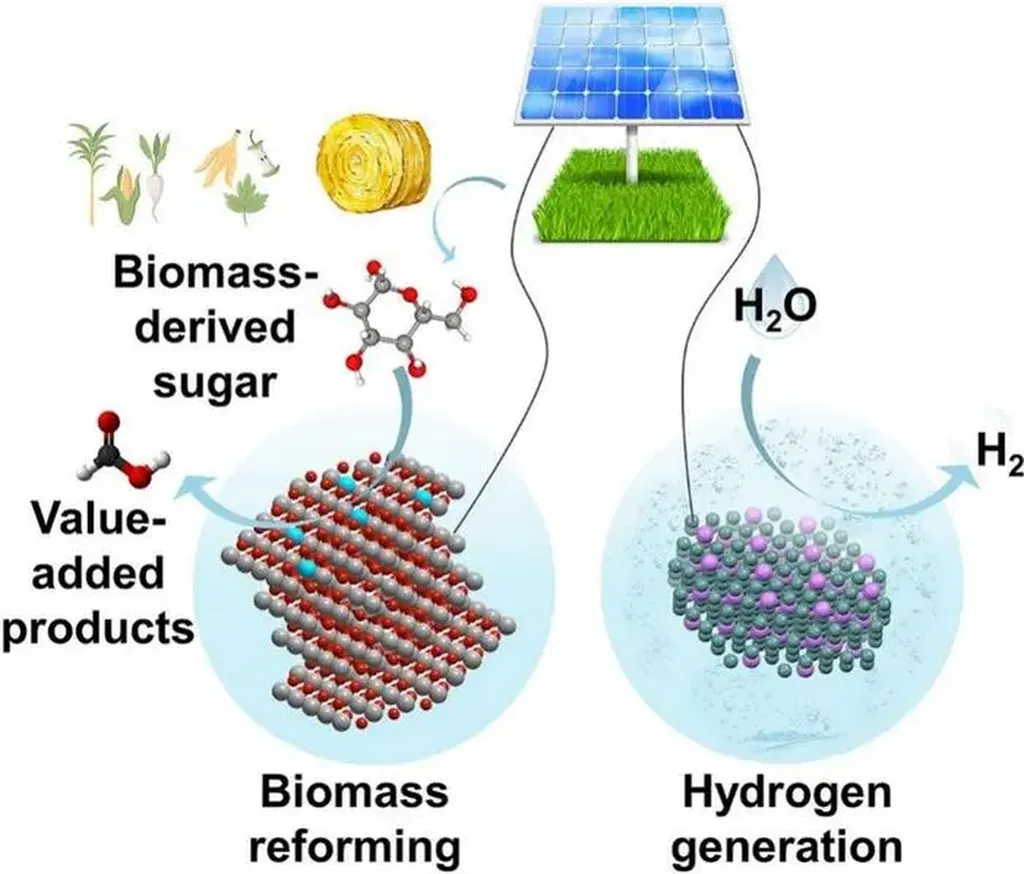

Researchers have cracked a long-standing barrier in green hydrogen production, slashing costs to a level that finally undercuts fossil fuels. A new system using sugars from agricultural waste has successfully produced green hydrogen at just $1.54 per kilogram, according to a recent report from Interesting Engineering. This breakthrough, achieved by selectively electrooxidizing glucose to formate instead of water to oxygen, removes the need for costly membranes and makes the process far more efficient than previous methods.

The innovation addresses one of the biggest hurdles in the green hydrogen sector: cost. Traditional electrolysis, which splits water into hydrogen and oxygen using renewable electricity, has struggled to compete economically with hydrogen derived from natural gas. “This could effectively end the decade-long economic standoff between clean energy and natural gas,” reports Interesting Engineering. The new process not only reduces costs but also leverages agricultural byproducts, adding a circular economy dimension to hydrogen production.

Experts say this advancement could accelerate the adoption of green hydrogen in hard-to-decarbonize industries such as steel, shipping, and chemicals, where electrification is not feasible. “Green hydrogen has the potential to be the oil of the decarbonized era,” according to the International Energy Agency. With costs now competitive, the technology is poised to move from pilot projects to full-scale industrial deployment, offering a viable path to net-zero emissions for sectors that have few alternatives.

This breakthrough arrives as global momentum builds for hydrogen as a key pillar of the energy transition. With policy support and private investment ramping up, green hydrogen is transitioning from promise to reality—just in time to meet the urgent demands of climate action.