In the realm of energy infrastructure, the reliability and safety of electronic components are paramount. A recent study led by Meng Han, a researcher affiliated with the University of Science and Technology of China, presents a novel approach to enhance the detection of tiny defects on Printed Circuit Boards (PCBs), which are integral to many energy systems. The research, published in the journal IEEE Transactions on Industrial Electronics, introduces a framework designed to improve the precision of defect detection, a critical factor in maintaining the integrity of electronic components used in energy technologies.

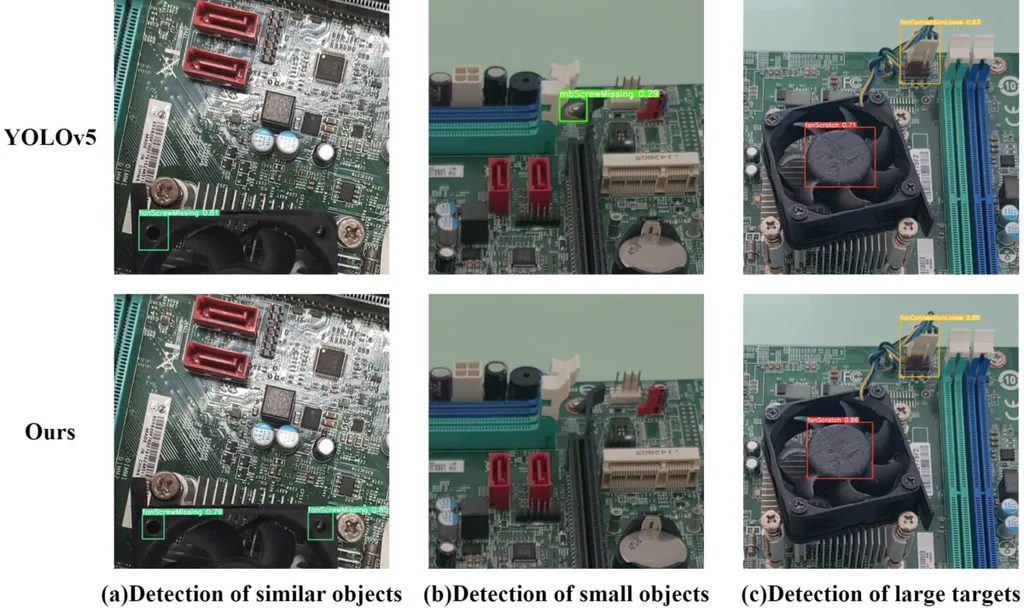

The study addresses the challenges posed by the small size, high texture similarity, and uneven scale distributions of defects on PCBs. The proposed framework, named SME-YOLO (Small-target Multi-scale Enhanced YOLO), is based on the YOLOv11n algorithm and incorporates several innovative components. The first key improvement is the use of Normalized Wasserstein Distance Loss (NWDLoss), which reduces the sensitivity of the Intersection over Union (IoU) metric to positional deviations in tiny objects. This enhancement allows for more accurate detection of small defects.

Another significant advancement is the replacement of the original upsampling module with the Efficient Upsampling Convolution Block (EUCB). The EUCB employs multi-scale convolutions to gradually recover spatial resolution and preserve edge and texture details for tiny defects. This improvement ensures that even the smallest defects are detected with high precision.

The study also introduces the Multi-Scale Focused Attention (MSFA) module, which is tailored to the specific spatial distribution of PCB defects. This module adaptively strengthens perception within key scale intervals, enabling efficient fusion of local fine-grained features and global context information. The MSFA module enhances the overall detection capability of the framework.

Experimental results on the PKU-PCB dataset demonstrate that SME-YOLO achieves state-of-the-art performance. Compared to the baseline YOLOv11n, SME-YOLO improves the mean Average Precision (mAP) by 2.2% and Precision by 4%. These improvements validate the effectiveness of the proposed method in detecting tiny defects on PCB surfaces.

The practical applications of this research for the energy sector are substantial. By improving the detection of tiny defects on PCBs, the SME-YOLO framework can enhance the reliability and safety of electronic components used in energy systems. This, in turn, can lead to more efficient and dependable energy infrastructure, reducing the risk of failures and improving overall system performance. The research highlights the importance of advanced detection technologies in maintaining the integrity of critical electronic components in the energy industry.

This article is based on research available at arXiv.