In the realm of advanced materials and manufacturing processes, a team of researchers from the National University of Science and Technology MISIS in Moscow has been exploring innovative techniques to enhance the properties of refractory metals. These scientists, led by Dr. A. V. Nokhrin, have been investigating the low-temperature Spark Plasma Sintering (SPS) of tungsten (W) and nickel (Ni) composite powders, with a focus on understanding the underlying mechanisms and optimizing the process parameters.

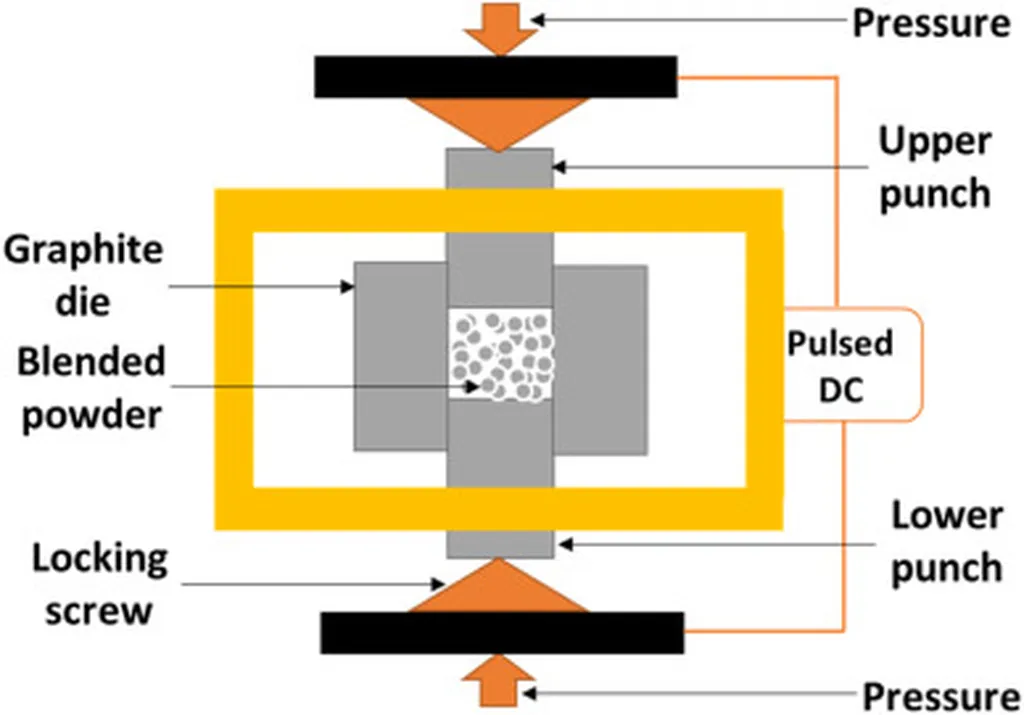

The researchers prepared tungsten-nickel composite powders using two distinct methods: simple mechanical mixing of W and Ni powders (W + Ni), and a more sophisticated approach involving the deposition of Ni onto the surface of submicron W particles, creating a core-shell structure (W@Ni). To minimize the presence of oxygen and oxides, the powders were annealed in hydrogen. The team then subjected these powders to solid-phase sintering at various temperatures (1000-1150°C), pressures (40-80 MPa), heating rates (50-500°C/min), and isothermal holding times (0-20 min). The chosen sintering temperatures corresponded to the onset of intense dissolution of W in Ni.

The study revealed that the activation energy of SPS for the mixed W + Ni powders was comparable to that of grain boundary diffusion, a process where atoms diffuse along the boundaries between grains in a material. In contrast, the primary mechanism driving the compaction of W@Ni particles during SPS was found to be Coble creep, a type of diffusion creep that occurs at low stresses and high temperatures. As the sintering temperature increased, so did the solubility of W in Ni, leading to a higher number of secondary Ni4W particles forming during the cooling process. Interestingly, the grain growth resulting from the sintering process had a relatively minor impact on the mechanical properties of the W alloy compared to the changes in its phase composition.

The practical implications of this research for the energy industry are significant. The development of advanced refractory metals with enhanced properties can lead to improved performance and longevity of components used in extreme environments, such as those found in nuclear reactors, gas turbines, and other high-temperature applications. The optimized SPS process parameters and the understanding of the underlying mechanisms can help manufacturers produce these advanced materials more efficiently and cost-effectively.

This research was published in the Journal of Alloys and Compounds, a peer-reviewed scientific journal dedicated to the study of alloys and composite materials. The findings contribute to the growing body of knowledge on advanced manufacturing techniques and materials, paving the way for innovations in the energy sector and beyond.

This article is based on research available at arXiv.