In a move that could significantly accelerate the commercialization of fusion energy, Commonwealth Fusion Systems (CFS) has announced a collaboration with NVIDIA and Siemens to develop a digital twin of its SPARC fusion machine. The partnership, unveiled during a keynote address at the CES technology show in Las Vegas, aims to leverage artificial intelligence (AI) and advanced data management tools to streamline the development of fusion energy.

CFS, a nuclear energy company spun out of the Massachusetts Institute of Technology (MIT) in 2018, will utilize Siemens’ Xcelerator portfolio of industrial software, including Designcenter NX for advanced product engineering and Teamcenter product lifecycle management (PLM) tools. These tools will enable CFS to create, catalog, and process machine designs and assemblies, which can then be integrated into modeling and simulation workflows enhanced with AI-enabled tools.

The digital twin will be powered by NVIDIA Omniverse libraries and OpenUSD, allowing CFS to integrate data with classical and AI-powered physics models. This virtual replica of SPARC will provide a platform for running simulations, testing hypotheses, and rapidly comparing experimental results with simulations. The goal is to expedite the analysis of data and refine functions, ultimately speeding up the commercialization of fusion energy.

Bob Mumgaard, CEO of CFS, emphasized the transformative potential of this collaboration. “CFS will be able to compress years of manual experimentation into weeks of virtual optimization using the digital infrastructure developed by NVIDIA and Siemens,” he said. “Through this collaboration, we’re demonstrating how AI and integrated digital engineering can accelerate progress from design to grid power. This will allow us to transform how we build and operate fusion machines in the race to commercial fusion.”

Rev Lebaredian, vice president of Omniverse and Simulation Technology at NVIDIA, highlighted the complexity of delivering commercial fusion. “By using Siemens NX software and NVIDIA Omniverse libraries to create a high-fidelity digital twin of SPARC, CFS will be able to accelerate its engineering and shorten the timeline to clean power,” he said.

The collaboration also extends to improving manufacturing processes and operations at CFS’s magnet factory in Devens, Massachusetts, using Siemens’ digital tools. Del Costy, president and managing director, Americas, for Siemens Digital Industries Software, noted, “By connecting Siemens Xcelerator with NVIDIA AI visualization libraries, we’re demonstrating that end-to-end digital workflows aren’t just efficient, they’re transformative. Fusion is complex, but data doesn’t lie. When you aggregate real manufacturing intelligence, apply AI, and run thousands of scenarios, you remove guesswork and accelerate innovation. This is the future of industrial engineering.”

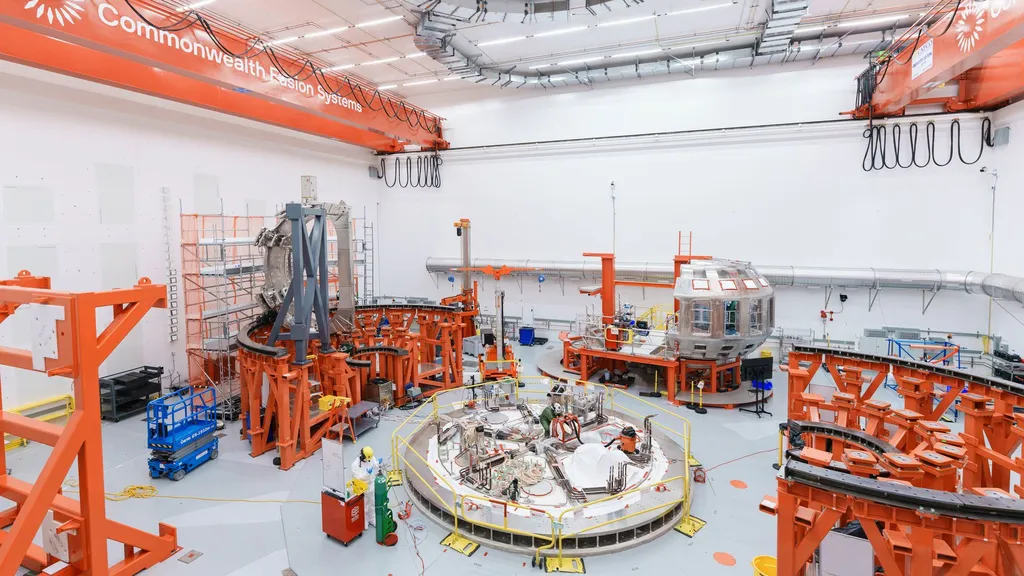

In a surprising reveal, CFS announced the installation of the first of 18 D-shaped toroidal field (TF) magnets needed for the SPARC machine. This milestone underscores the maturity of CFS’s high-temperature superconducting (HTS) magnet technology, which enables the creation of smaller, stronger magnets, making fusion power more commercially viable and affordable. Mumgaard expects all 18 magnets to be installed by the end of the summer, marking a significant step forward in the development of fusion energy.

This collaboration between CFS, NVIDIA, and Siemens could reshape the landscape of the energy sector by demonstrating the potential of AI and digital twins in accelerating the development of clean energy technologies. As fusion energy gains more backers, including technology companies like Google, the integration of advanced digital tools and AI could become a standard practice in the quest for sustainable and efficient energy solutions.