Researchers from the RWTH Aachen University in Germany have made significant strides in understanding the degradation of Cr2AlC coatings, a material of interest for both nuclear and gas turbine industries. Devi Janani Ramesh, Sameer Aman Salman, and Jochen M. Schneider have employed a novel approach to quantify the three-dimensional changes that occur during the oxidation of these coatings, providing valuable insights into their performance and longevity.

Cr2AlC is a promising candidate for coatings in accident-tolerant nuclear fuel claddings and turbine blades due to its excellent high-temperature properties. However, its degradation in oxidizing environments has been difficult to characterize quantitatively. The researchers addressed this challenge by using a correlative tomography-based mass balance framework, which integrates volumetric, structural, and compositional data to track changes during oxidation.

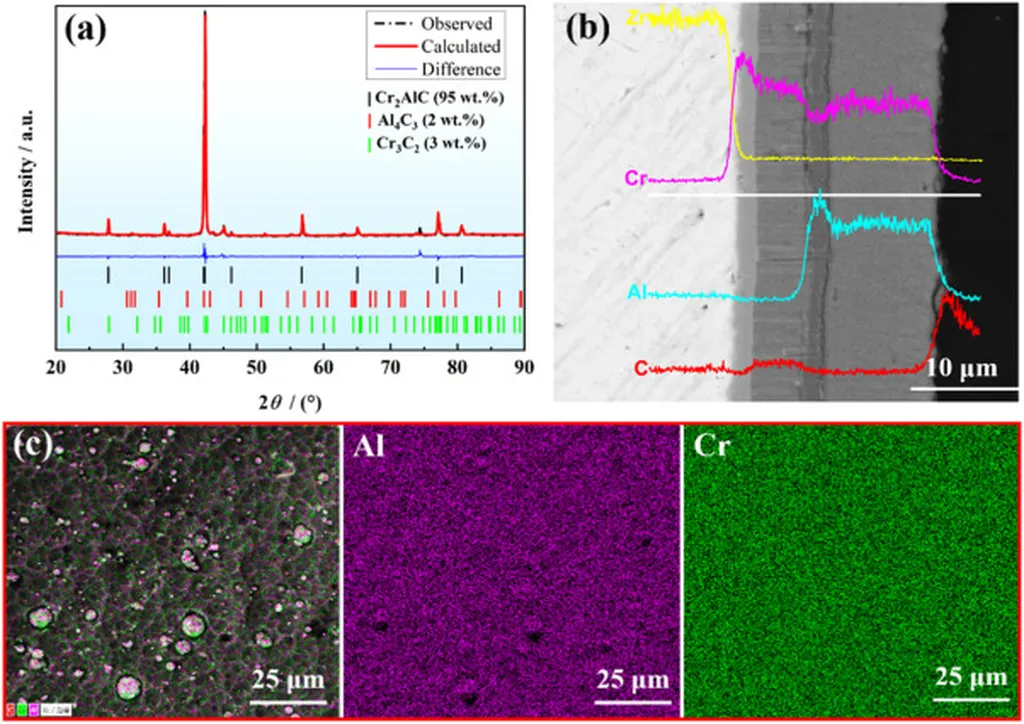

The team analyzed Cr2AlC coatings with two different grain morphologies: equiaxed and columnar. They found that while both types of coatings formed Cr7C3 during oxidation, pores formed exclusively in the columnar coatings. The researchers estimated the expected volume of Cr7C3 by assuming that the oxidation process involves the deintercalation of aluminum, leading to the formation of an oxide scale and Al-O-C-N precipitates. This process transforms the aluminum-deintercalated Cr2AlC into Cr7C3.

In equiaxed coatings, the predicted volume of Cr7C3 matched the measured volume within a margin of 3 ± 3%, confirming that the formation of Cr7C3 is driven by aluminum deintercalation. Despite the smaller molar volume of Cr7C3 compared to Cr2AlC, the absence of pores in equiaxed coatings suggests that the transformation shrinkage is accommodated by a reduction in coating thickness.

In contrast, the predicted volume of Cr7C3 in columnar coatings exceeded the measured value by 22 ± 4%. Additionally, the pore volume expected from transformation shrinkage alone was 13-16% lower than measured. This discrepancy indicates that only partial aluminum deintercalation occurred, and pre-existing defects in the columnar coatings clustered to form pores.

The researchers’ combined methodology provides a general route to quantitatively resolve degradation mechanisms in materials subjected to oxidizing environments. This understanding is crucial for the energy industry, as it can inform the development of more durable coatings for nuclear fuel claddings and turbine blades, ultimately improving the safety and efficiency of energy generation.

The research was published in the journal Acta Materialia, a leading publication in the field of materials science and engineering.

This article is based on research available at arXiv.