Researchers from ETH Zurich, including Barış Kavas, Efe C. Balta, Lars Witte, Michael R. Tucker, John Lygeros, and Markus Bambach, have developed a novel control system for the laser powder bed fusion (LPBF) process, a type of additive manufacturing technology. Their work, published in the journal Additive Manufacturing Letters, focuses on stabilizing the temperature between layers of material during the printing process, which can significantly impact the quality and properties of the final product.

The team’s innovative closed-loop feedback controller uses a thermal camera to measure the temperature between layers and adjusts the laser power or dwell time accordingly. In heating mode, the controller dynamically adjusts the laser power to maintain a preset reference temperature. In cooling mode, it increases the dwell time between layers to allow the material to cool down. This switching between heating and cooling modes is governed by a feedback optimization control algorithm and a triggering algorithm, respectively.

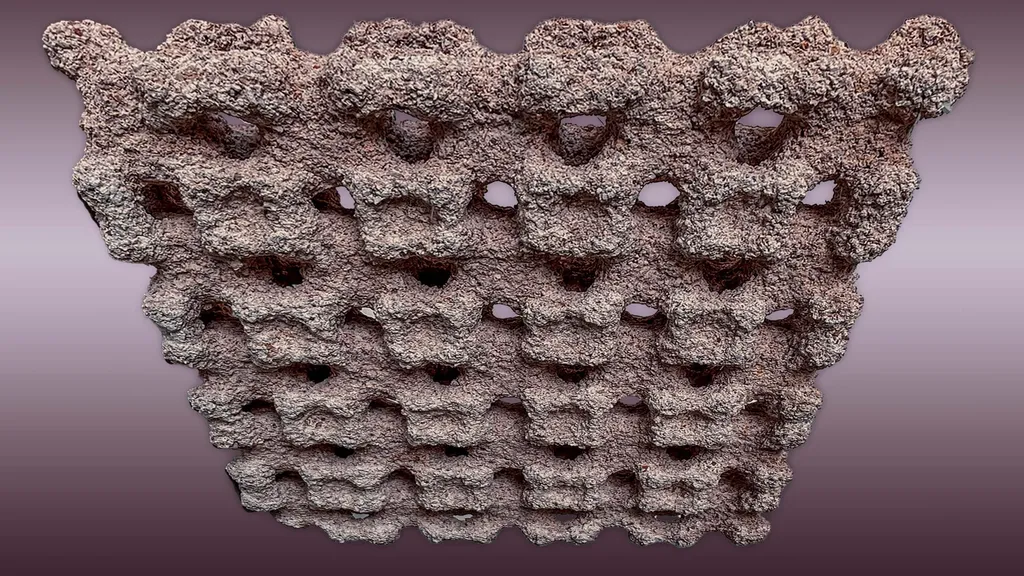

The researchers tested the controller on both supported and unsupported overhanging parts to evaluate its performance and the effect of support structures on thermal behavior. They found that the controller effectively stabilized the interlayer temperature across varying cross-sectional areas, keeping it within the material’s stable processing zone. Supported parts showed reduced overheating but consumed more energy and material, while unsupported parts stabilized temperature faster but had longer build times due to increased dwell time.

This research highlights the potential for improved temperature control in additive manufacturing processes, which can lead to better quality products and more efficient use of materials and energy. The practical applications for the energy sector could include more efficient production of complex, high-performance components for energy generation, storage, and distribution systems. By optimizing the LPBF process, manufacturers could reduce material waste, energy consumption, and production time, ultimately lowering costs and environmental impact.

This article is based on research available at arXiv.