Researchers Thibaud Plantegenet, Mihai Arghir, Mohamed-Amine Hassini, and Pascal Jolly from the Université de Poitiers in France have conducted an experimental study on the thermal unbalance effects in rotors supported by journal bearings. Their work, published in the journal Mechanical Systems and Signal Processing, provides insights that could be valuable for the energy industry, particularly in the design and operation of rotating machinery such as turbines and generators.

The study focused on understanding how thermal unbalance, caused by differential heating in journal bearings, affects both rigid (short) and flexible (long) rotors. The researchers conducted experiments using a short rotor at 7,000 revolutions per minute (rpm) and a long rotor at 6,600 rpm. The short rotor showed an increase in synchronous amplitudes with slight phase changes before stabilization. During coast-down, the pronounced hysteresis of the synchronous amplitudes confirmed that the amplitude increase was due to thermal unbalance.

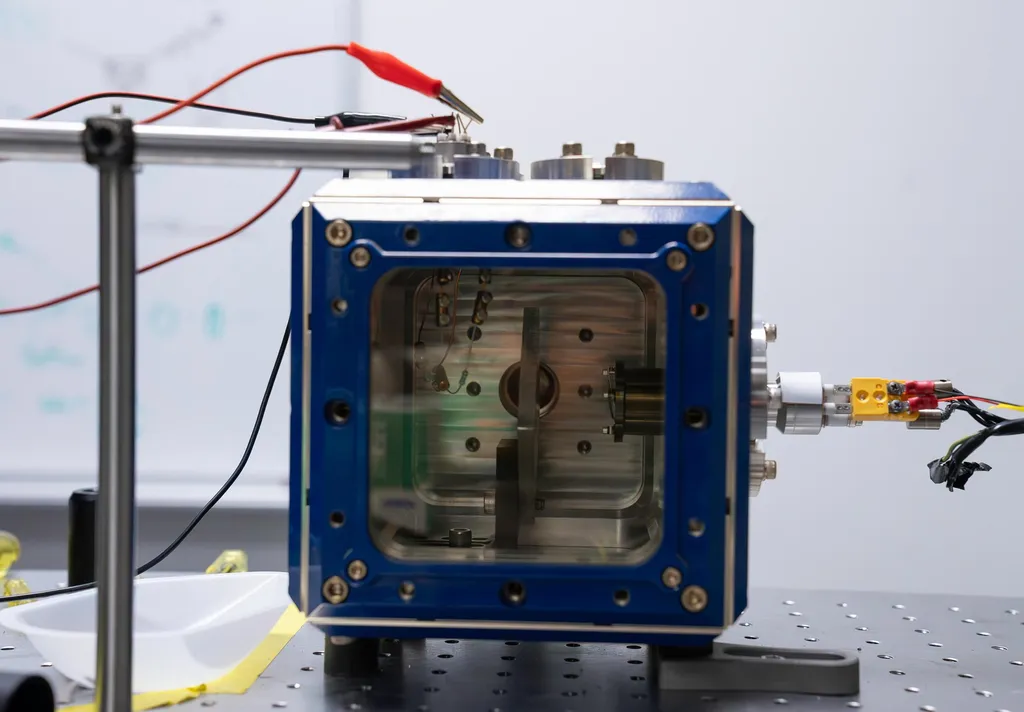

For the long rotor, the researchers observed a stabilized response when the start-up time was 180 seconds. However, when the start-up time was reduced to 80 seconds, an instability occurred, leading to contact with the journal bearing. The study measured synchronous amplitudes and phases, mean temperatures, maximum temperature differences in the journal and bearing, and phase lags between the high spot and the hot spot.

The findings of this research have practical applications for the energy sector, particularly in the design and operation of rotating machinery. Understanding thermal unbalance effects can help in optimizing the performance and longevity of equipment such as turbines and generators. By ensuring proper start-up times and managing thermal unbalance, energy companies can reduce the risk of equipment failure and improve overall efficiency.

The research was published in the journal Mechanical Systems and Signal Processing, providing a valuable contribution to the field of mechanical engineering and rotating machinery.

This article is based on research available at arXiv.