Researchers from the University of Science and Technology of China, including Long-Zhou Huang, Xu Yang, Min-Qiang Jiang, and Yun-Jiang Wang, along with Matteo Baggioli from the University of Rome Tor Vergata, have introduced a new method to predict plasticity in disordered solids, such as glasses. Their work, published in the journal Nature Communications, offers a more robust approach to anticipating plastic events, which could have significant implications for the energy industry, particularly in materials science and engineering.

Plasticity in materials refers to their ability to undergo permanent deformation without breaking. Predicting when and where this will occur is crucial for understanding and improving the performance of materials used in various energy applications, from structural components to storage systems. Previous research has shown that vortex-like topological defects in the vibrational modes of a two-dimensional glass under shear can correlate with plastic events, offering a potential route to predict them. However, many of these vortices are not related to plasticity and arise from the underlying structure of the modes, limiting their predictive power.

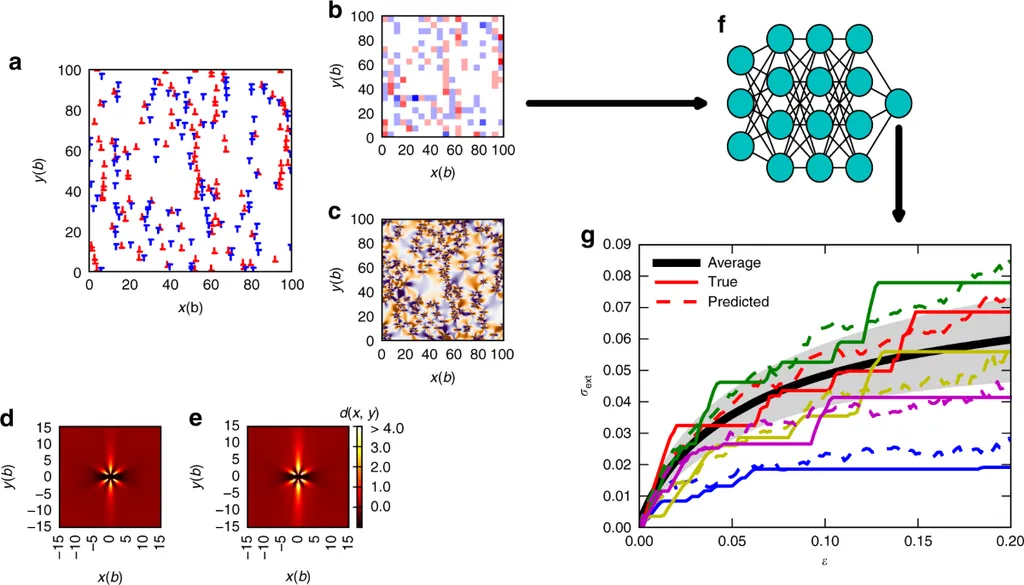

The researchers introduced a geometrical filter based on the Nye dislocation density. When applied to the vibrational modes, this filter removes the spurious defects and reveals the true plastic precursors. Using simulations of a two-dimensional model glass, they demonstrated that this filtered approach consistently outperforms the conventional vortex-based method, particularly at small strains and when focusing on genuine plastic stress drops. This means that the new method can more accurately predict plastic events from the initial, undeformed state of the material.

The practical applications of this research for the energy sector are significant. By better predicting plasticity, engineers can design materials that are more resistant to deformation and failure, leading to safer and more efficient energy systems. For example, in the oil and gas industry, pipelines and storage tanks must withstand extreme pressures and temperatures without deforming or leaking. Similarly, in renewable energy, the blades of wind turbines must maintain their structural integrity despite constant exposure to wind forces. By applying the insights from this research, materials used in these and other energy applications can be improved, leading to more reliable and durable infrastructure.

In conclusion, the researchers have developed a more robust tool for predicting plasticity in disordered solids, which could have wide-ranging implications for the energy industry. By better understanding and anticipating plastic events, engineers can design materials that are better suited to the demanding conditions of energy production, storage, and transmission. This research represents a significant step forward in the field of materials science and offers promising avenues for future exploration.

This article is based on research available at arXiv.