Researchers from the Aristotle University of Thessaloniki in Greece have developed a novel system for sorting waste electrical and electronic equipment (WEEE), with a particular focus on battery recycling. The team, led by Panagiotis Giannikos and including Lampis Papakostas, Evangelos Katralis, and others, has integrated advanced imaging, artificial intelligence, and robotic technologies to create a solution that addresses the growing challenges in battery recycling.

The research, published in the journal “Robotics and Computer-Integrated Manufacturing,” presents an integrated system that employs X-ray imaging, AI-based object detection and segmentation, and Delta robot manipulation. The system is designed to accurately identify and sort batteries from various types of WEEE, which is becoming increasingly critical due to the rapid growth in battery usage and the limited availability of natural resources.

The system works by moving devices along a conveyor belt through a high-resolution X-ray imaging system. The X-ray transmission dual energy imaging subsystem, combined with advanced pre-processing algorithms, enables high-contrast image reconstruction. This allows for effective differentiation of dense and thin materials in WEEE. The YOLO and U-Net models then precisely detect and segment battery-containing items.

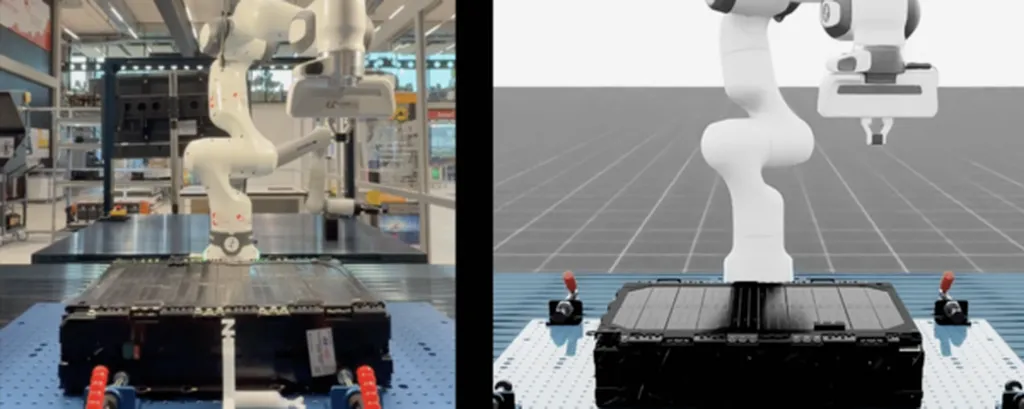

An intelligent tracking and position estimation algorithm guides a Delta robot equipped with a suction gripper to selectively extract and properly discard the targeted devices. This approach has been validated in a photorealistic simulation environment developed in NVIDIA Isaac Sim and on the real setup, demonstrating its effectiveness in real-world applications.

The practical applications for the energy sector are significant. As battery energy densities continue to rise, improper handling during recycling poses significant safety hazards, including potential fires at recycling facilities. This system provides a fully autonomous solution capable of accurately identifying and sorting batteries across diverse WEEE types, enhancing safety and efficiency in recycling processes.

The researchers highlight that while numerous systems have been proposed for battery detection and removal from WEEE recycling lines, a fully autonomous solution has yet to be realized until now. This novel approach integrates advanced technologies to address the challenges in battery recycling, offering a promising solution for the energy industry.

Source: Robotics and Computer-Integrated Manufacturing

This article is based on research available at arXiv.