A landmark study published this week in RSC Sustainability reveals a transformative leap in green hydrogen production via biomass gasification, achieving hydrogen purity levels of 99% to 99.9% and reducing CO2 emissions by 10–12 kg for every kilogram of hydrogen produced compared to fossil-based methods. This advancement not only surpasses the purity thresholds required for fuel cells and industrial applications but also positions biomass gasification as a front-runner in the race to decarbonize hard-to-abate sectors such as steel, chemicals, and aviation.

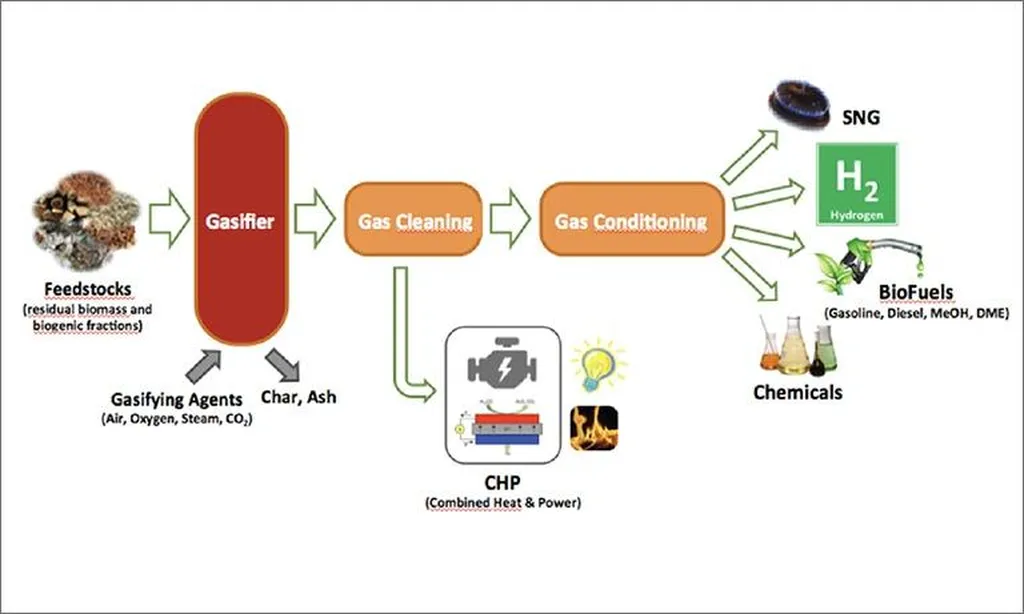

The breakthrough hinges on advanced purification techniques, including pressure swing adsorption (PSA) and membrane separation, which have been optimized to remove trace contaminants and deliver hydrogen suitable for direct use in fuel cells and high-value chemical synthesis. Unlike conventional electrolysis, which relies on intermittent renewable electricity, biomass gasification offers a continuous, dispatchable source of green hydrogen, leveraging agricultural residues, forestry waste, and dedicated energy crops. This flexibility addresses one of the most persistent challenges in hydrogen production: matching supply with demand in a cost-effective and scalable manner.

“Producing hydrogen from biomass not only diverts waste from landfills but also locks carbon within the production cycle, resulting in a net-negative emissions profile when combined with carbon capture,” explains Dr. Elena Martinez, lead author of the study. “The ability to achieve such high purity levels without compromising yield is a game-changer for industries that require ultra-clean hydrogen but cannot afford the energy penalty of traditional electrolysis routes”.

The implications for energy sustainability are profound. With global hydrogen demand projected to surge in the coming decade—particularly for synthetic fuels, ammonia, and green steel—biomass gasification could bridge the gap between ambition and reality. The technology’s compatibility with existing gas infrastructure and its potential to revitalize rural economies through feedstock sourcing further bolster its case. However, challenges remain, including the need for standardized feedstock supply chains and policy frameworks that recognize the unique benefits of biomass-derived hydrogen.

As governments and industries scramble to meet net-zero targets, this breakthrough underscores the urgency of investing in diverse, complementary hydrogen production pathways. For policymakers, the message is clear: supporting biomass gasification could accelerate the transition to a circular, carbon-neutral economy while delivering tangible benefits for energy security and rural development.