Researchers from the University of Paris-Saclay, including Abderraouf Bounjad, Aoran Wu, Cyril Chevarin, Patrick Guenoun, Florent Mallogi, Jean-Pierre Mericq, Charaff Merzougui, Denis Bouyer, and Hervé Henry, have conducted a numerical study to better understand the Non-Solvent Induced Phase Separation (NIPS) process used in membrane fabrication. Their work, published in the Journal of Membrane Science, sheds light on how the relative mobilities of chemical components can significantly impact the final structure and properties of membranes.

The study focuses on the NIPS process, where a polymer film is exposed to a non-solvent, triggering a phase separation that results in a polymer-rich phase and a polymer-poor phase. This process is crucial in creating the intricate structures found in filtration membranes. The researchers used 2D and 3D numerical simulations of the ternary Cahn-Hilliard model to investigate how the relative mobilities of the polymer and solvent/non-solvent affect the phase separation patterns.

Their findings reveal that the relative mobilities of these components can dramatically influence whether phase separation occurs and the nature of the resulting patterns. For instance, the simulations showed that the final membrane structure can range from isolated pores to a bicontinuous network, where both the polymer-rich and polymer-poor phases form interconnected structures. This bicontinuous pattern was observed over a wide range of initial film compositions, suggesting that it is a common outcome of the NIPS process under certain conditions.

The researchers also quantified the transport properties of the polymer-rich and polymer-poor domains, which is essential for understanding how effectively the membrane can filter substances. The connectivity of the final pattern was analyzed using a quantitative indicator, providing insights into the membrane’s structural integrity and performance.

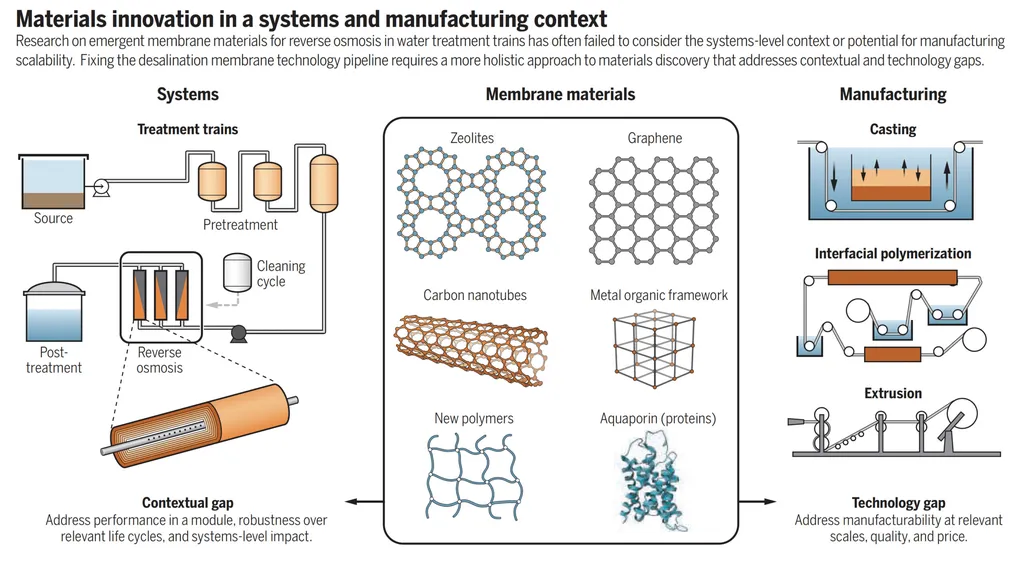

For the energy industry, this research is particularly relevant in the development of advanced filtration membranes used in various applications, such as water desalination, gas separation, and energy storage. Understanding and controlling the phase separation process can lead to the design of membranes with optimized structures and enhanced performance, ultimately contributing to more efficient and sustainable energy solutions. The study highlights the importance of considering the relative mobilities of chemical components in the membrane fabrication process to achieve desired properties and functionalities.

This article is based on research available at arXiv.