In the quest for sustainable energy solutions, a team of researchers from the University of Illinois at Urbana-Champaign, led by Zahra Teimouri and Mahtab Masouminia, has made significant strides in the field of electrochemical CO2 reduction (CO2R). Their work, published in the journal Nature Catalysis, focuses on developing stable and efficient catalysts for CO2 electrolysis, a process that could revolutionize the energy industry by enabling the production of carbon-neutral fuels.

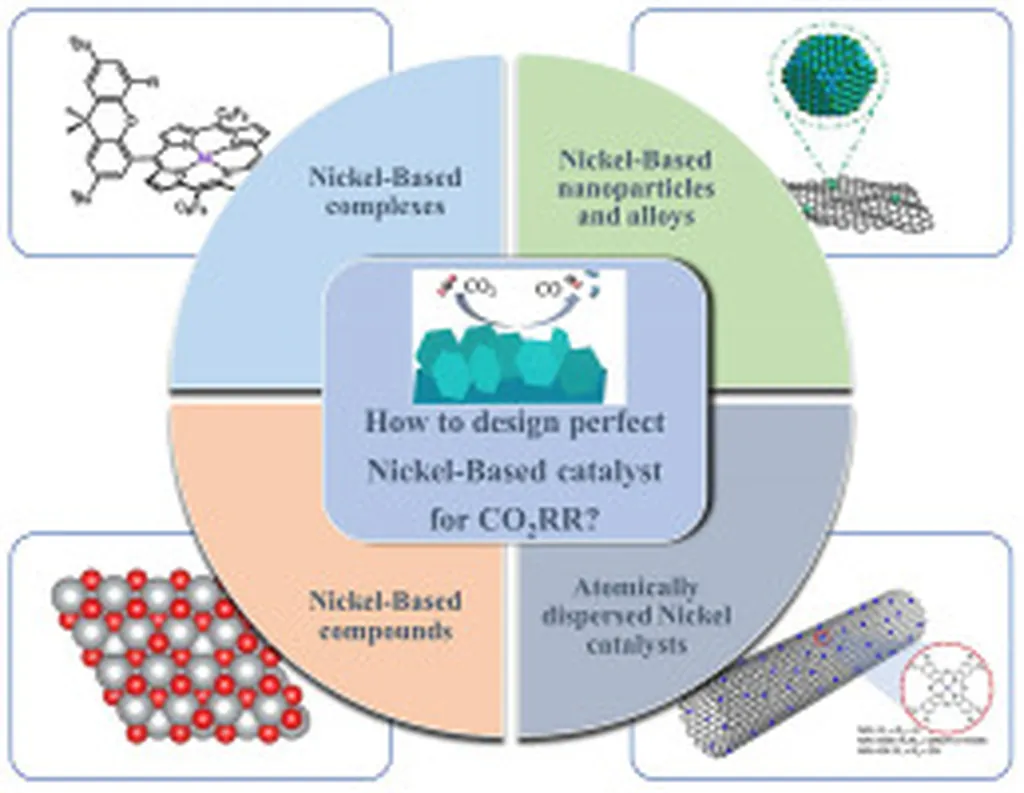

The researchers have developed an atomically dispersed nickel-nitrogen-carbon (Ni-NC) catalyst using a scalable synthesis approach with two different carbon supports: carbon nanotubes and carbon black. When carbon nanotubes were used as the support, the resulting Ni-NCNT electrode achieved impressive results. It demonstrated a partial current density toward CO of 558 mA cm-2 with 92 percent Faradaic efficiency toward CO at a cell voltage of 3.2 V. The energy efficiency toward CO was 39 percent at a total current density of 607 mA cm-2. The MEA (Membrane Electrode Assembly) reactor using this catalyst showed stable operation at 100 mA cm-2 over 210 hours, outperforming previously reported Ni-NC catalysts.

The researchers employed advanced techniques such as Focused Ion Beam Scanning Electron Microscopy (FIB-SEM) tomography to understand the role of the catalyst support in electrode performance. They found that the Ni-NCNT electrode’s superior performance was due to improved CO2 diffusion and a more uniform current-density distribution compared to the Ni-NCB electrode prepared with carbon black as the support. COMSOL Multiphysics simulations using 3D reconstructed images of the catalyst layers from FIB-SEM tomography supported these findings.

The stability and performance of the Ni-NCNT catalyst compare favorably to state-of-the-art Ag-based catalysts. Importantly, a bottom-up cost analysis estimates the purchase cost of the Ni-NCNT catalyst to be about 589 USD per kg, substantially lower than the 1900 USD per kg estimated for Ag-based catalysts. This cost advantage makes the Ni-NCNT catalyst a promising candidate for commercial applications in the energy sector.

The practical applications of this research are significant for the energy industry. The development of efficient and stable catalysts for CO2 electrolysis could enable the production of carbon-neutral fuels, contributing to the decarbonization of chemical manufacturing. This technology could be integrated into existing energy infrastructure, providing a sustainable alternative to fossil fuels. The use of scalable synthesis methods and cost-effective materials further enhances the potential for widespread adoption of this technology.

In summary, the research conducted by Teimouri, Masouminia, and their team represents a significant advancement in the field of CO2 electrolysis. Their development of the Ni-NCNT catalyst offers a promising solution for the energy industry, paving the way for more sustainable and efficient energy production. The findings were published in the journal Nature Catalysis, providing a valuable resource for further research and development in this critical area.

This article is based on research available at arXiv.